Product Description

Introducing our high-quality Shaft, designed for various applications in the field of motors and gears. This versatile product is an essential component for any home appliance, ensuring smooth and efficient operation.

Our Shaft is expertly crafted using premium materials, guaranteeing durability and long-lasting performance. With its precise dimensions and excellent load-bearing capacity, it seamlessly integrates with motors and gears, providing optimal power transmission.

Featuring a sleek design, this Shaft is not only functional but also aesthetically pleasing. Its compact size allows for easy installation and compatibility with a wide range of home appliances

With our discounted price, you can now enhance the performance of your home appliances without breaking the bank. Don’t miss out on this incredible offer!

Keywords: Shaft, Axis, Motor Shaft, Gear

| Available Material | 1. Stainless Steel: AISI303, AISI304, AISI316, AISI416, AISI420,etc. |

| 2. Free Cutting Steel:12L14,1215,etc. | |

| 3. Steel:C45(K1045), C20,etc | |

| 4. Aluminum: Al6061, Al6063, etc. | |

| 5. Carbon Steel:AISI1006,AISI1571,AISI1571,etc. | |

| 6. Alloy Steel: SCM435,10B21,etc. | |

| 7. According to customer’s requirement | |

| Finish | Electroplating: Zinc Plating, Ni Plating, Electroless Nickel Plating, Zn-Ni Alloy Plating, Tin Plating, Copper-plating, Hot-dip Galvanizing, Black Oxide Coating, Black Anodizing, etc |

| Rust Preventive Oil | |

| Testing Equipment | CMM, Projector, Pull Tester, Projecting Apparatus |

| Salt Spray Test, Durometer, Coating Analyzer, Tensile Machine | |

| Management System | ISO9001 / IATF16949 |

| Certification | SGS, RoHS, Material Certification, PPAP |

| Production Capability | Auto Lathe Turning: ODΦ1.0-20mm, Tolerance. ± 0.01mm |

| CNC Lathe Turning: ODΦ1.0-460mm, Tolerance. ± 0.005mm | |

| CNC Milling:800x600mm (LxW), Tolerance.±0.05mm | |

| Grinding: Tolerance. ± 0.002mm | |

| Screw Cold Heading and Rolling: Metric 0.8-M16 | |

| Injection: 300T Max | |

| Stamping:2 50T Max |

1.

Location

Kexionda Electric Machinery Manufacturing Co., Ltd. (KXD) was established in 1998 and is located in the hinterland of the Pearl River CHINAMFG in South China. It is a professional enterprise that develops and produces micromotors. It now has a factory area of more than 10,000 square meters, more than 200 employees, and an annual output of 5 million motors. It mainly produces single-phase series motors (universal motors) and permanent magnet-brushed DC motors. The products are suitable for household appliances, commercial appliances, and electric equipment, such as mixers, egg beaters, meat grinders, meat mincers, ice crushers, paper shredders, bean grinders, soy milk machines, cooking machines, cloth machines, laboratory homogenizer and a series of electric products.

2.

“integrity and pragmatism”

Since its establishment, KXD has continued to innovate and win the market with integrity. The company comprehensively implements modern management, conducts production and sales based on the principle of benefiting customers, produces key parts of products by itself, continuously introduces automated production equipment, takes “quality and service” as its life, “integrity and pragmatism” as its foundation, and through its Design, production, and management are integrated to meet customer delivery deadlines to the greatest extent, effectively control product quality and reduce costs.

3.

Production standards

KXD strictly implements national standards during the production process, establishes and maintains the effective operation of the quality management system, and all products have 100% passed domestic CCC certification. All export products comply with Rohs and can pass EMC, UL, CE, VDE, and other certification requirements.

4.

Customer – first

At present, our company has dedicated project personnel to track product development, production, and after-sales service throughout the entire process, and is committed to providing customers with high-quality product solutions.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 5.33/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What advancements in screw jack technology have improved efficiency and reliability?

Advancements in screw jack technology have led to significant improvements in efficiency and reliability. Here are some key advancements that have contributed to these improvements:

- High-Efficiency Ball Screws: Traditional screw jacks often used trapezoidal or square threads, which had relatively lower efficiency due to higher friction. However, the introduction of high-efficiency ball screws in screw jack designs has greatly improved efficiency. Ball screws offer low friction and higher efficiency, resulting in reduced power consumption and improved overall system efficiency.

- Improved Lubrication Systems: Proper lubrication is crucial for the smooth operation and longevity of screw jacks. Advancements in lubrication systems, such as the use of self-lubricating materials, improved lubricants, and better sealing mechanisms, have enhanced the reliability and maintenance intervals of screw jacks. These advancements minimize wear, reduce friction, and ensure consistent performance over extended periods.

- Materials and Coatings: The use of advanced materials and coatings has significantly improved the durability and reliability of screw jacks. Components made from high-strength alloys, such as stainless steel or hardened steel, can withstand higher loads and resist wear. Additionally, coatings like zinc plating or epoxy coatings provide corrosion resistance, extending the lifespan of screw jacks in challenging environments.

- Integrated Sensors and Feedback Systems: Integration of sensors and feedback systems in screw jacks has improved their reliability and control. Position sensors, load sensors, and torque sensors can be integrated into screw jacks to provide real-time feedback and monitoring. This enables precise positioning, load measurement, and the ability to detect and respond to abnormal operating conditions, ensuring safe and reliable operation.

- Automation and Control Integration: The integration of screw jacks with advanced automation and control systems has improved efficiency and reliability. Motorized screw jacks can be integrated with programmable logic controllers (PLCs) or computer numerical control (CNC) systems, enabling precise and synchronized movements, remote operation, and automation. This integration minimizes human error, enhances repeatability, and optimizes the overall efficiency of screw jack systems.

- Design Optimization: Advancements in computer-aided design (CAD) and simulation tools have allowed for the optimization of screw jack designs. Finite element analysis (FEA) and virtual prototyping enable the evaluation and refinement of various design parameters, resulting in improved load-bearing capabilities, reduced weight, and enhanced structural integrity. These design optimizations contribute to increased efficiency and reliability.

These advancements in screw jack technology have collectively improved efficiency, reliability, and overall performance. Manufacturers continue to innovate and refine screw jack designs to meet the evolving needs of various industries, ensuring that screw jacks remain a reliable and efficient solution for lifting and adjusting loads.

How do screw jacks enhance the performance of lifting and leveling applications?

Screw jacks are versatile mechanical devices that enhance the performance of lifting and leveling applications in several ways. Here are some ways in which screw jacks contribute to improved performance:

- Precise Positioning: Screw jacks offer precise positioning control, allowing for accurate adjustment of height or level. The threaded screw mechanism provides fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is crucial in applications where precise alignment, leveling, or height adjustment is required.

- Heavy Load Capacity: Screw jacks are capable of lifting and supporting heavy loads. They are designed to handle substantial weight and provide reliable load-bearing capabilities. The mechanical advantage of the screw thread allows for efficient transfer of force, enabling screw jacks to handle loads that would be impractical or challenging for other lifting mechanisms.

- Stability and Safety: Screw jacks offer stability and safety during lifting and leveling operations. The threaded screw mechanism ensures that the load remains secure and stable in the desired position, minimizing the risk of accidental movement or shifting. Screw jacks are designed with safety features such as locking mechanisms or braking systems to prevent unintended lowering or sudden movements, enhancing overall safety for both operators and the lifted load.

- Adjustability and Flexibility: Screw jacks provide adjustability and flexibility in lifting and leveling applications. They can be easily adjusted to accommodate different heights or levels, making them suitable for a wide range of applications. Screw jacks are available in various sizes, load capacities, and configurations, allowing for customization and adaptation to specific requirements.

- Reliability and Durability: Screw jacks are known for their reliability and durability. They are constructed with robust materials and designed to withstand heavy loads, frequent use, and harsh operating conditions. The screw thread mechanism is inherently resistant to wear and provides excellent load-holding capabilities, ensuring long-term performance and reliability.

- Manual or Motorized Operation: Screw jacks can be operated manually or with motorized systems, providing flexibility in choosing the appropriate mode of operation based on the specific application. Manual screw jacks are often used when precise control is required, while motorized screw jacks offer increased speed and automation for lifting or leveling larger or heavier loads.

By offering precise positioning, high load capacity, stability, adjustability, reliability, and flexibility in operation, screw jacks significantly enhance the performance of lifting and leveling applications. Their versatility and ability to handle heavy loads make them a preferred choice in various industries where controlled lifting, leveling, or positioning is essential.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by Dream 2024-04-25

China Best Sales Customized Steel Metal Helical Screw Shaft Used for Convyor System twin screw extruder shaft

Product Description

Customized Steel metal helical screw shaft used for convyor system

This product is 1 customized screw helical Shaft made of heavy steel of Q345 used for the Conveyor system and ground digger , a 1.2kw laser cutting machine cuts it, and a professional machine strength forms the spiral shape and global standard welding skill finishes it. The cutting edge of this screw plate is very smooth and the tolerance is controlled within 0.05~0.1mm according to the drawing required measure, which is a very high standard in the whole industry. The professional welding standard makes it look very nice.

We also offer various customized laser cutting, forming, bending, and welding services for steel, copper, aluminum, etc materials, and the thickness can be arranged from 1~50mm.

Welcome to contact us for further discussion !!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do screw jacks compare to other methods of lifting and adjusting loads?

When comparing screw jacks to other methods of lifting and adjusting loads, several factors come into consideration. Here’s a comparison of screw jacks with other commonly used methods:

- Hydraulic Systems: Screw jacks offer several advantages over hydraulic systems:

- Control and Precision: Screw jacks provide precise control and incremental adjustments. Hydraulic systems, on the other hand, may have limitations in terms of fine-tuning and precise positioning.

- Self-Locking: Screw jacks have a self-locking feature, which means they can hold positions without the need for continuous hydraulic pressure. Hydraulic systems typically require constant pressure to maintain position, which can be a disadvantage in certain applications.

- Simplicity and Maintenance: Screw jacks are generally simpler in design and require less maintenance compared to hydraulic systems. Hydraulic systems involve additional components such as pumps, hoses, valves, and hydraulic fluid, which can introduce complexity and maintenance requirements.

- Load Capacity: Screw jacks are available in a wide range of load capacities, making them suitable for both light-duty and heavy-duty applications. Hydraulic systems can handle higher loads but may be less suitable for precise adjustments in lighter load ranges.

- Pneumatic Systems: Screw jacks offer several advantages over pneumatic systems:

- Precision and Control: Screw jacks provide precise and controlled adjustments, allowing for accurate positioning. Pneumatic systems may have limitations in terms of fine-tuning and precise control.

- Self-Locking: Screw jacks have a self-locking feature, which allows them to hold positions without the need for continuous pneumatic pressure. Pneumatic systems require continuous pressure to maintain position, which can be a drawback in certain applications.

- Energy Efficiency: Screw jacks are typically more energy-efficient compared to pneumatic systems since they do not require a constant supply of compressed air.

- Load Capacity: Screw jacks can handle a wide range of load capacities, making them suitable for various applications. Pneumatic systems may have limitations in terms of handling heavy loads.

- Electric Actuators: Screw jacks offer several advantages over electric actuators:

- Load Capacity: Screw jacks are capable of handling high loads and are suitable for heavy-duty applications. Electric actuators may have limitations in terms of load capacity.

- Self-Locking: Screw jacks have a self-locking feature, which allows them to hold positions without the need for continuous electric power. Electric actuators may require continuous power to maintain position.

- Precision and Control: Screw jacks provide precise control and incremental adjustments. Electric actuators can offer precise positioning but may have limitations in terms of fine-tuning and incremental adjustments.

- Cost-Effectiveness: Screw jacks are often more cost-effective compared to electric actuators, making them a preferred choice in certain applications.

It’s important to note that the choice between screw jacks and other methods depends on the specific requirements of the application, such as load capacity, precision, control, maintenance, and cost considerations. Each method has its strengths and limitations, and manufacturers and engineers evaluate these factors to determine the most suitable solution for a particular lifting or adjusting task.

Can screw jacks be customized or integrated into larger systems for specific uses?

Yes, screw jacks can be customized or integrated into larger systems to meet specific requirements and applications. Their modular nature and versatility allow for various customization and integration possibilities. Here are some ways screw jacks can be customized or integrated into larger systems:

- Load Capacity Customization: Screw jacks can be customized to handle specific load capacities. Manufacturers can design and manufacture screw jacks with different load ratings to accommodate the requirements of a particular application. By customizing the load capacity, screw jacks can be optimized for lifting and supporting a wide range of loads, from light loads in precision applications to heavy machinery in industrial settings.

- Mounting and Connection Options: Screw jacks can be customized to have different mounting and connection options. This allows for seamless integration into existing systems or specific applications. Manufacturers can provide various mounting configurations, such as flange mounts, base mounts, trunnion mounts, or clevis ends, to ensure easy installation and compatibility with the surrounding equipment or structures.

- Stroke Length Customization: The stroke length of a screw jack can be customized to suit specific requirements. The stroke length refers to the distance the lifting screw travels during the jack’s operation. By customizing the stroke length, screw jacks can be tailored to the required vertical movement or extension needed in a particular application. This customization ensures optimal performance and efficiency in lifting or positioning tasks.

- Specialized Materials and Coatings: Screw jacks can be customized with specialized materials or coatings to enhance their performance in specific environments. For example, in corrosive or harsh conditions, screw jacks can be manufactured using corrosion-resistant materials such as stainless steel or coated with protective finishes. This customization ensures the longevity and reliability of screw jacks in demanding applications.

- Integration with Motorized Systems: Screw jacks can be integrated with motorized systems to automate the lifting and positioning processes. By adding electric or hydraulic motorization, screw jacks can be controlled and synchronized with other components or systems, providing precise and automated operations. This integration enables efficient and programmable movements, reducing manual labor and increasing productivity.

- Control and Monitoring Integration: Screw jacks can be integrated with control and monitoring systems for enhanced functionality and safety. By incorporating sensors, limit switches, or feedback mechanisms, screw jacks can provide real-time feedback on position, load, or other parameters. This integration allows for accurate control, monitoring, and protection of the screw jack and the larger system it is a part of.

The customization and integration options for screw jacks make them highly adaptable to specific uses and applications. Manufacturers often work closely with customers to understand their requirements and provide tailored solutions that optimize the performance, efficiency, and reliability of screw jacks within larger systems.

What factors should be considered when selecting the right screw jack for an application?

When selecting the right screw jack for an application, several factors should be taken into consideration. These factors help ensure that the chosen screw jack meets the specific requirements of the application. Here are the key factors to consider:

- Load Capacity: Determine the maximum load that the screw jack needs to lift or support. Consider both the static load (the weight of the load when stationary) and the dynamic load (additional forces or vibrations that may be present during operation). Select a screw jack with a load capacity that exceeds the application’s requirements to ensure safe and reliable operation.

- Travel Distance: Determine the required travel distance or height adjustment range of the screw jack. Consider both the minimum and maximum travel distances needed for the application. Ensure that the selected screw jack can provide the required travel distance without exceeding its mechanical limits.

- Speed Requirements: Consider the desired operating speed of the screw jack. Determine whether the application requires slow and precise movement or faster operation. The speed of the screw jack is influenced by factors such as the pitch of the screw and the rotational speed of the input device. Select a screw jack that can operate within the desired speed range without compromising other performance factors.

- Precision Needs: Assess the required level of precision for the application. Determine the allowable tolerance and backlash requirements. The precision of a screw jack is influenced by factors such as the pitch of the screw, the quality of the thread, and the presence of additional components such as limit switches or position sensors. Choose a screw jack that can achieve the desired precision level while maintaining stability and load capacity.

- Environmental Conditions: Consider the environmental conditions in which the screw jack will operate. Factors such as temperature, humidity, dust, and corrosive substances can affect the performance and durability of the screw jack. Select a screw jack that is designed to withstand the specific environmental conditions of the application.

- Mounting and Integration: Evaluate the available space for mounting the screw jack and consider the required integration with other components or systems. Determine whether the screw jack needs to be vertically mounted, horizontally mounted, or at an angle. Consider any specific mounting or interface requirements and ensure that the selected screw jack can be easily integrated into the existing system or structure.

- Safety and Compliance: Ensure that the chosen screw jack complies with safety standards and regulations applicable to the specific industry or application. Consider safety features such as self-locking mechanisms, overload protection, and emergency stop options. Verify that the manufacturer or supplier provides adequate documentation and certifications.

- Cost and Budget: Consider the budget and cost-effectiveness of the screw jack. Compare the prices and features of different screw jack models and brands. Evaluate the long-term maintenance and operational costs, including factors such as lubrication requirements and expected lifespan.

By carefully considering these factors, it is possible to select the right screw jack that meets the load capacity, travel distance, speed, precision, environmental, mounting, safety, and budget requirements of the specific application.

editor by Dream 2024-04-24

China factory Cylinder Liner Rail Linear Shaft for Machinery twin screw extruder shaft

Product Description

How do screw jacks ensure controlled and synchronized movement in multi-jack systems?

Screw jacks are capable of ensuring controlled and synchronized movement in multi-jack systems through various mechanisms and techniques. These systems are commonly used in applications where multiple screw jacks need to work together to lift or position a load. Here’s how screw jacks achieve controlled and synchronized movement in multi-jack systems:

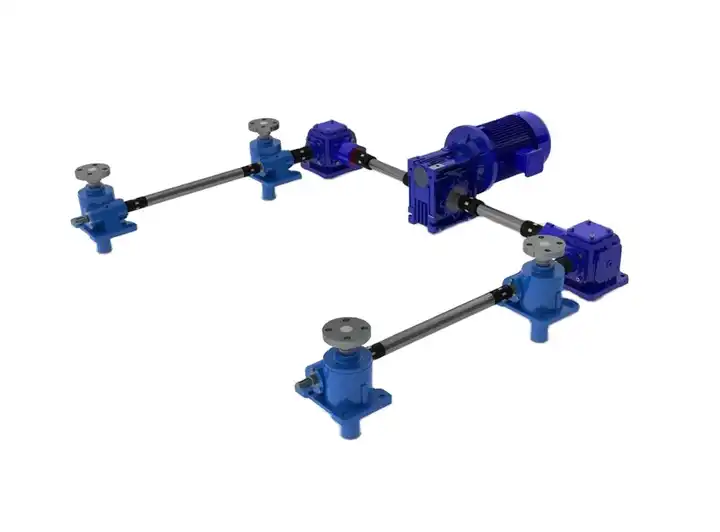

- Mechanical Synchronization: Screw jacks can be mechanically linked in a multi-jack system to ensure synchronized movement. This can be achieved through the use of rigid couplings, connecting rods, or gear mechanisms that interconnect the input shafts of individual screw jacks. As a result, when one screw jack is operated to lift or lower the load, the mechanical linkage transfers the motion to the other screw jacks, causing them to move in sync. This ensures that all jacks contribute proportionally to the load and maintain a consistent lifting height.

- Electrical Synchronization: In addition to mechanical synchronization, screw jacks can also be electrically synchronized in multi-jack systems. This is typically achieved through the use of motorized screw jacks controlled by a centralized control system. Each motorized screw jack is equipped with position sensors or encoders that provide feedback on their current position. The control system receives this feedback and adjusts the motor speed and direction for each screw jack to ensure synchronized movement. Electrical synchronization enables precise control and allows for adjustments to be made dynamically, compensating for any variations in load distribution or environmental conditions.

- Load Sharing Mechanisms: In multi-jack systems, load sharing mechanisms can be employed to distribute the weight evenly among the screw jacks. Load sharing mechanisms can include load sensors or load cells that measure the individual loads on each jack. The control system then adjusts the lifting force applied by each screw jack to ensure equal distribution of the load. This prevents overloading of any individual jack and promotes balanced movement in the system.

- Position Feedback and Control: Screw jacks in multi-jack systems can be equipped with position feedback devices, such as linear encoders or limit switches, that provide information on the position of the load. This feedback is used by the control system to precisely control the movement of the screw jacks, ensuring that they reach and maintain the desired positions. By continuously monitoring the position feedback, the control system can make adjustments to keep the jacks synchronized and maintain the desired level of control.

- Control System Integration: A centralized control system can be used to integrate and coordinate the operation of multiple screw jacks in a multi-jack system. This control system can utilize programmable logic controllers (PLCs) or computer numerical control (CNC) systems to manage the movement, synchronization, and safety aspects of the screw jacks. The control system enables precise control, real-time monitoring, and the implementation of safety features, enhancing the overall performance and reliability of the multi-jack system.

By employing these mechanisms and techniques, screw jacks ensure controlled and synchronized movement in multi-jack systems. These systems find applications in various industries, such as heavy lifting, material handling, and industrial automation, where precise positioning and synchronized operation are critical requirements.

How do screw jacks enhance the performance of lifting and leveling applications?

Screw jacks are versatile mechanical devices that enhance the performance of lifting and leveling applications in several ways. Here are some ways in which screw jacks contribute to improved performance:

- Precise Positioning: Screw jacks offer precise positioning control, allowing for accurate adjustment of height or level. The threaded screw mechanism provides fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is crucial in applications where precise alignment, leveling, or height adjustment is required.

- Heavy Load Capacity: Screw jacks are capable of lifting and supporting heavy loads. They are designed to handle substantial weight and provide reliable load-bearing capabilities. The mechanical advantage of the screw thread allows for efficient transfer of force, enabling screw jacks to handle loads that would be impractical or challenging for other lifting mechanisms.

- Stability and Safety: Screw jacks offer stability and safety during lifting and leveling operations. The threaded screw mechanism ensures that the load remains secure and stable in the desired position, minimizing the risk of accidental movement or shifting. Screw jacks are designed with safety features such as locking mechanisms or braking systems to prevent unintended lowering or sudden movements, enhancing overall safety for both operators and the lifted load.

- Adjustability and Flexibility: Screw jacks provide adjustability and flexibility in lifting and leveling applications. They can be easily adjusted to accommodate different heights or levels, making them suitable for a wide range of applications. Screw jacks are available in various sizes, load capacities, and configurations, allowing for customization and adaptation to specific requirements.

- Reliability and Durability: Screw jacks are known for their reliability and durability. They are constructed with robust materials and designed to withstand heavy loads, frequent use, and harsh operating conditions. The screw thread mechanism is inherently resistant to wear and provides excellent load-holding capabilities, ensuring long-term performance and reliability.

- Manual or Motorized Operation: Screw jacks can be operated manually or with motorized systems, providing flexibility in choosing the appropriate mode of operation based on the specific application. Manual screw jacks are often used when precise control is required, while motorized screw jacks offer increased speed and automation for lifting or leveling larger or heavier loads.

By offering precise positioning, high load capacity, stability, adjustability, reliability, and flexibility in operation, screw jacks significantly enhance the performance of lifting and leveling applications. Their versatility and ability to handle heavy loads make them a preferred choice in various industries where controlled lifting, leveling, or positioning is essential.

Can you explain the basic principle behind the operation of a screw jack?

The basic principle behind the operation of a screw jack is the conversion of rotational motion into linear motion. A screw jack consists of a threaded shaft, known as the screw, and a nut that engages with the screw’s threads. When the screw is rotated, it moves the nut linearly along its threads, resulting in linear displacement. Here are some key points regarding the basic principle of operation for a screw jack:

- Rotational Motion: The operation of a screw jack begins with the application of rotational motion to the screw. This can be achieved through various means, such as manually turning a handle, using an electric motor, or employing hydraulic or pneumatic systems. The rotational motion is typically applied to the top end of the screw.

- Threaded Shaft: The screw in a screw jack is a threaded shaft with helical grooves running along its length. The threads can be either square or trapezoidal in shape. The pitch of the screw refers to the distance traveled along the screw’s axis for each complete revolution. The pitch determines the linear displacement achieved per rotation.

- Nut Engagement: The nut is a component that engages with the screw’s threads. It is typically a cylindrical or rectangular block with a threaded hole that matches the screw’s threads. The nut is free to move linearly along the screw’s length when the screw is rotated.

- Linear Motion: As the screw is rotated, the nut moves along the screw’s threads, causing linear displacement. The direction and magnitude of the displacement depend on the rotational direction and the pitch of the screw. Clockwise rotation typically results in upward linear displacement, while counterclockwise rotation leads to downward displacement.

- Mechanical Advantage: One of the advantages of a screw jack is its ability to provide a mechanical advantage. The pitch of the screw determines the distance traveled per revolution. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased, allowing for the lifting or lowering of heavier loads with relatively less rotational effort.

- Self-Locking: The friction between the screw and the nut helps to maintain the position of the load once the rotational force is removed. This self-locking characteristic of screw jacks allows them to hold loads in position without requiring continuous power or external braking mechanisms.

In summary, the basic principle behind the operation of a screw jack involves the conversion of rotational motion into linear motion. By rotating the screw, the nut moves along the screw’s threads, resulting in linear displacement. The pitch of the screw determines the distance traveled per revolution, and the self-locking nature of the screw and nut interface helps maintain the position of the load.

editor by CX 2024-04-12

China Professional Plug Screw Discharge Screw Shaft for Wood Fibre Defibrator Machine extruder screw shaft

Product Description

Feed Screw

Tech Information:

| Component | C | Cr | Mo | Si | Mn | N | S | P | Re | The material is high alloy wear-resistant steel, which is the exclusive material developed by our company for many years. It has been tested by the market and its service life is 3 times that of Sweden SS2387-13 |

| Detection result | 1.98 | 26.26 | 1.22 | 0.65 | 0.82 | 0.23 | 0.018 | 0.017 | some | |

| Acceptability limit | 1.75-2.4 | 24-28 | 0.8-1.5 | 0.35-1 | 0.5-1.0 | 0.2-0.35 | <0.03 | <0.03 | some |

Main material:

1Cr 13, 4Cr 9 Si2, 0Cr 18 Ni 9, 1Cr 18 Ni 9 Ti, 0Cr 18 Ni 12 Mo 2 Ti,

1Cr17 Ni 14 Mo 2 Cu 2, 3Cr 18 Mn 12 Si 2 N, 3Cr 24 Ni 7 SiNRe , 2Cr 25 Ni 20 Si 2,

4Cr 26 Ni 35 NbW, 4Cr 28 Ni 48 W 5 Si 2, 40CrMo, 42CrMnSiMo, etc.

Advantages:

1. HRC>70

2.Made by super wear-resistant alloy steel which improves production efficiency effectively

3.We have rich technical experience to produce Plug screw of various sizes

Know us more by the following:

We are Factory who mainly producing Special Steel parts For MDF HDF Plant & Paper machine , which like Segment/Plug Screw/Shaft ribbon feeder/PLUG SCREW CASING/Discharge screw shaft And so on.

Our company has very rich technical experience, More,the quality and service have always been at the leading domestic level. Lifespan of our products is longer than others.

Our Quality is No1 in China, Plug screw life time is 3 times of original, Since 2011, we have more than 200 customers working with us till now in China , whole china have 500 MDF factories, More than half of them are our partners, Only great quality and service wins that.

For Oversaes’ business, we have professional workers who are experts on the export procedure. Our customers come from Russia, Belarus,France, Spain ,Mexico. Malaysia,Sri Lanka ,Vietnam and so on.

So Just feel freely to contact us,It will be our honor to hear from you too

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Application: | Defibrator Machine |

| Hardness: | HRC>70 |

| Quality Certificates: | ISO9001 |

| Lifespan: | 12 Monthes Around |

| Customization: | Yes |

| Customization: |

Available

| Customized Request |

|---|

How do screw jacks contribute to the safety of tasks like vehicle maintenance?

Screw jacks play a crucial role in ensuring the safety of tasks like vehicle maintenance. They provide stability, lifting capabilities, and precise control, which are essential for safe and efficient maintenance operations. Here’s how screw jacks contribute to safety in vehicle maintenance:

- Stability and Load Capacity: Screw jacks are designed to provide high stability and support heavy loads. When used in vehicle maintenance, they offer a solid and secure platform for lifting and supporting the vehicle. This stability ensures that the vehicle remains steady during maintenance tasks, reducing the risk of accidents or injuries caused by uncontrolled movement or instability.

- Precise Height Adjustment: Screw jacks allow for precise height adjustment, enabling mechanics to position the vehicle at the desired working height. This precise control ensures that the vehicle is at an optimal height for accessing various components, performing inspections, or conducting repairs. It helps maintain a comfortable working posture for mechanics, minimizing the risk of strain or injury.

- Locking Mechanisms: Screw jacks often incorporate locking mechanisms to securely hold the lifted load in position. These locking mechanisms prevent accidental lowering of the vehicle during maintenance tasks, providing an additional layer of safety. Even in the event of power loss or system failure, the locking mechanism ensures that the vehicle remains elevated, reducing the risk of injury or damage.

- Even Weight Distribution: When multiple screw jacks are used in a synchronized system, they distribute the load evenly, ensuring balanced support. This even weight distribution minimizes stress on individual components and prevents overloading, reducing the risk of equipment failure or accidents caused by imbalanced loads.

- Integration with Safety Systems: Screw jacks can be integrated with safety systems to enhance overall safety during vehicle maintenance tasks. For example, limit switches or proximity sensors can be used to prevent the screw jacks from exceeding their maximum or minimum height limits. Emergency stop buttons or safety interlocks can be integrated into the control system, allowing immediate halting of the lifting operation in case of emergencies or hazardous situations.

The combination of stability, precise control, locking mechanisms, even weight distribution, and integration with safety systems makes screw jacks a reliable and safe solution for vehicle maintenance tasks. They provide mechanics with a secure working platform, reduce the risk of accidents, and contribute to the overall safety and efficiency of vehicle maintenance operations.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

Can screw jacks be adapted for both vertical and horizontal lifting applications?

Yes, screw jacks can be adapted for both vertical and horizontal lifting applications. Screw jacks are versatile mechanical devices that can be configured and mounted in various orientations to accommodate different lifting requirements. Here’s how screw jacks can be adapted for vertical and horizontal lifting applications:

- Vertical Lifting: Screw jacks are commonly used for vertical lifting applications. In vertical lifting configurations, the screw jack is mounted in a vertical position, with the load being lifted or lowered along the vertical axis. Vertical lifting applications include lifting platforms, stage equipment, heavy machinery, and other scenarios where vertical movement is required. Screw jacks designed for vertical lifting typically feature self-locking mechanisms to ensure load stability when the screw is not being rotated. The load is supported by the screw jack’s structure, which is constructed to handle the vertical forces exerted during lifting.

- Horizontal Lifting: Screw jacks can also be adapted for horizontal lifting applications. In horizontal lifting configurations, the screw jack is mounted in a horizontal position, and the load is moved horizontally or at an angle. Horizontal lifting applications can include conveyor systems, sliding gates, adjustable workstations, and other scenarios where linear movement is required along a horizontal plane. To adapt a screw jack for horizontal lifting, additional support mechanisms may be employed to counteract the gravitational forces acting on the load. These support mechanisms can include guide rails, linear guides, or additional bracing to maintain stability and control during horizontal movement.

- Angular Lifting: Screw jacks can be further adapted for angular lifting applications where the load needs to be lifted or lowered along an inclined or diagonal plane. Angular lifting configurations require careful consideration of the load’s weight distribution, the angle of inclination, and the stability of the supporting structure. By appropriately positioning and supporting the screw jack, angular lifting applications can be achieved with precision and control.

- Mounting Flexibility: Screw jacks offer flexibility in terms of mounting options, allowing them to be adapted for various orientations. The mounting flexibility enables screw jacks to be integrated into different lifting systems and structures. Depending on the specific requirements of the application, screw jacks can be mounted using flanges, brackets, or other mounting accessories. This adaptability facilitates the use of screw jacks in both vertical and horizontal lifting applications.

In summary, screw jacks can be adapted for both vertical and horizontal lifting applications. By considering factors such as load requirements, gravitational forces, stability needs, and mounting flexibility, screw jacks can be configured and mounted to provide stable and controlled lifting in various orientations.

editor by CX 2024-03-26

China factory CZPT Arrow Customized 40CrNiMoA Extruder Spline Screw Shaft for Plastic Extruder Machine Pelletizing screw and axle

Product Description

Overview

Product Description

Screw elements are crucial components in twin screw extruders, playing a pivotal role in determining the quality and output of plastic products. These elements are responsible for various essential functions, including plastic molecular mixing, cutting, spreading, and facilitating reactions among the materials. To ensure exceptional production quality, our company has leveraged years of experience, incorporated valuable insights from international practices, and carefully considered customer requirements to develop a comprehensive range of processing screw elements

our meticulously designed screw elements offer a multitude of benefits, prominently featuring exceptional self-cleaning performance. This remarkable attribute guarantees the integrity of the entire production line. Furthermore, our screw elements boast a combination of superior characteristics, including optimum parameters, high self-cleaning efficiency, remarkable wear resistance, and outstanding corrosion resistance.

Through the thoughtful integration of our expertise and customer feedback, we have successfully created a refined selection of screw elements that not only meet but exceed industry standards. These elements ensure the highest quality and output for plastic products, empowering our clients to achieve superior results in their operations.

Screw for Plastic Extruder

1.All sizes of the screw are 38CrMnAlA Nitrided steel +Special Alloy Spraying Welding on the whole screw thread surface.

2. For twin screw barrel material: A. Integral barrel Standard Alloy spraying B. Two parts Bimetallic sleeve C. High Calcium filler abrasion resistant .

3. For single screw barrel: Main Barrel + feeding sleeve zone as basic structure with A type as standard, A: Integral barrel Standard Alloy spraying B:Two parts Bimetallic sleeve .

Basic Info.

| Place of Origin: ZheJiang , China | Brand Name: Arrow |

| Condition: New | Material: 40CrNiMoA |

| Weight (KG): 50 | Spare Parts Type: Barrel |

| Video outgoing-inspection: Provided |

Machinery Test Report: Provided |

| Warranty:1 year | Key Selling Points: Sustainable |

| Applicable Industries: Manufacturing Plant, Machinery Repair Shops |

Item: Bi-metal screw and barrel |

| Material for screw: 38CrMnAlA Nitrided steel |

Material for barrel: 40CrNiMoA+SKDII with heat treatment |

| Screw finish: Nitrogen-filled (0.50~0.70mm depth) |

Core of the screw: Auto control for temperature |

| Screw type: Single/ Double |

Rotate speed of screw: 0-48 |

| Double screw type: Conical/Parallel |

Barrel design for double screw: One body/two parts |

Application:

-For wear application:

Tool Steel: W6Mo5Cr4V2

PM-HIP material: WR5, WR13, WR14, CPM10V, CPM9V.

-For corrosion application:

38CrMoAla

PM-HIP material: WR4, WR13, WR14, CPM10V, CPM9V.

-For wear and corrosion application:

PM-HIP material: WR13, WR14, CPM10V, CPM9V.

-Other materials:

Stainless Steel:316L,440C etc.

Key Features:

- Tool steel, the steel has a high hardenability and thermal cracking resistance, the steel contains a higher content of tungsten, molybdenum,chromium and alum, good wear resistance, toughness is relatively weakened, with good heat resistance.

- High hardness,

- HRC up to 65.

Service

| 24-hour Hotline No matter when and where you are, call us and we can find our service to you. |

Pre-sales Consultation We have 5 sales people online, and whether you have any question can be solved through online communication, and welcome to your consultation. |

After-sales Services

you can receive products to our company and we will help |

FAQ

How long does it take to get my products since I paid for them?

—According to your order, we will give you a reasonable delivery date.

How is your after-sale service?

—You will get our help in time as long as you find something wrong about our produces. Believe us, you deserve the best.

What machine does the product apply to?

—Twin Screw Extruder Machine.

Certification

Exhibition

Company Profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online 24/7 Installation Guide |

|---|---|

| Warranty: | 1 Year |

| Standard: | GB, JIS |

| Samples: |

US$ 99999/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What advancements in screw jack technology have improved efficiency and reliability?

Advancements in screw jack technology have led to significant improvements in efficiency and reliability. Here are some key advancements that have contributed to these improvements:

- High-Efficiency Ball Screws: Traditional screw jacks often used trapezoidal or square threads, which had relatively lower efficiency due to higher friction. However, the introduction of high-efficiency ball screws in screw jack designs has greatly improved efficiency. Ball screws offer low friction and higher efficiency, resulting in reduced power consumption and improved overall system efficiency.

- Improved Lubrication Systems: Proper lubrication is crucial for the smooth operation and longevity of screw jacks. Advancements in lubrication systems, such as the use of self-lubricating materials, improved lubricants, and better sealing mechanisms, have enhanced the reliability and maintenance intervals of screw jacks. These advancements minimize wear, reduce friction, and ensure consistent performance over extended periods.

- Materials and Coatings: The use of advanced materials and coatings has significantly improved the durability and reliability of screw jacks. Components made from high-strength alloys, such as stainless steel or hardened steel, can withstand higher loads and resist wear. Additionally, coatings like zinc plating or epoxy coatings provide corrosion resistance, extending the lifespan of screw jacks in challenging environments.

- Integrated Sensors and Feedback Systems: Integration of sensors and feedback systems in screw jacks has improved their reliability and control. Position sensors, load sensors, and torque sensors can be integrated into screw jacks to provide real-time feedback and monitoring. This enables precise positioning, load measurement, and the ability to detect and respond to abnormal operating conditions, ensuring safe and reliable operation.

- Automation and Control Integration: The integration of screw jacks with advanced automation and control systems has improved efficiency and reliability. Motorized screw jacks can be integrated with programmable logic controllers (PLCs) or computer numerical control (CNC) systems, enabling precise and synchronized movements, remote operation, and automation. This integration minimizes human error, enhances repeatability, and optimizes the overall efficiency of screw jack systems.

- Design Optimization: Advancements in computer-aided design (CAD) and simulation tools have allowed for the optimization of screw jack designs. Finite element analysis (FEA) and virtual prototyping enable the evaluation and refinement of various design parameters, resulting in improved load-bearing capabilities, reduced weight, and enhanced structural integrity. These design optimizations contribute to increased efficiency and reliability.

These advancements in screw jack technology have collectively improved efficiency, reliability, and overall performance. Manufacturers continue to innovate and refine screw jack designs to meet the evolving needs of various industries, ensuring that screw jacks remain a reliable and efficient solution for lifting and adjusting loads.

Can you provide real-world examples of machinery or structures that use screw jacks?

Yes, screw jacks are commonly used in various machinery and structures for lifting, lowering, and positioning applications. Here are some real-world examples of machinery and structures that utilize screw jacks:

- Industrial Machinery: Screw jacks are widely used in industrial machinery and equipment. They are employed in material handling systems, assembly lines, packaging machines, and conveyors to lift or lower components, adjust working heights, or provide precise positioning. Screw jacks are also used in presses, injection molding machines, and die-casting equipment to apply controlled force or pressure.

- Construction and Infrastructure: In the construction industry, screw jacks are used in various applications. They are utilized in formwork systems to support and adjust the height of concrete molds during construction. Screw jacks are also employed in scaffolding systems to provide stability and height adjustment. In addition, they are utilized in bridge construction and maintenance to lift and position heavy components or to create temporary supports.

- Aerospace and Defense: Screw jacks find application in aerospace and defense industries. They are used in aircraft maintenance and assembly for tasks such as raising or lowering landing gear, adjusting wing flaps, or positioning aircraft components. Screw jacks are also utilized in missile launch systems, satellite deployment mechanisms, and radar systems.

- Automotive and Transportation: Screw jacks play a role in the automotive and transportation sectors. They are used in vehicle lifting systems, such as car lifts or hydraulic ramps, for maintenance and repair operations. Screw jacks are also employed in adjustable-height truck trailers, lifting platforms for disabled access vehicles, and loading dock levelers.

- Stage and Entertainment: In the stage and entertainment industry, screw jacks are utilized for stage rigging and set construction. They are employed to lift and position lighting fixtures, sound equipment, and scenery elements. Screw jacks provide precise control over the elevation and alignment of stage components, facilitating dynamic performances and efficient setup.

- Medical and Rehabilitation: Screw jacks find application in medical and rehabilitation equipment. They are used in patient lifts and adjustable hospital beds to facilitate safe patient transfers and positioning. Screw jacks also play a role in rehabilitation equipment, such as lifting platforms for physical therapy or adjustable exercise machines.

These are just a few examples of the many applications of screw jacks in various industries. The versatility, reliability, and precise control offered by screw jacks make them suitable for a wide range of machinery and structures where lifting, lowering, or positioning operations are required.

How do screw jacks handle variations in load, speed, and precision?

Screw jacks are designed to handle variations in load, speed, and precision through several mechanisms and features. Here’s how screw jacks handle these variations:

- Load Variations: Screw jacks are capable of handling different load variations. The load capacity of a screw jack depends on factors such as the mechanical strength of the components, the thread design, and the material properties. By selecting the appropriate screw jack with the required load capacity and considering factors such as the load distribution, safety factors, and duty cycle, variations in load can be accommodated within the specified limits.

- Speed Variations: Screw jacks can operate at different speeds based on the application requirements. The speed of a screw jack is influenced by factors such as the pitch of the screw, the rotational speed of the input device, and the mechanical advantage of the system. By adjusting the rotational speed of the input device or selecting screw jacks with different pitch options, variations in speed can be achieved. It is important to note that higher speeds may affect the efficiency, accuracy, and load capacity of the screw jack system.

- Precision: Screw jacks offer precise positioning capabilities. The linear displacement achieved per revolution of the screw can be accurately controlled. This precision is achieved through the pitch of the screw, which determines the linear displacement per rotation. By selecting screw jacks with suitable pitch options and incorporating additional components such as limit switches or position sensors, precise positioning can be achieved with minimal backlash or play. It is important to consider the required level of precision and the specific application’s tolerance requirements when choosing the appropriate screw jack.

- Adjustability: Screw jacks provide adjustability to accommodate variations in load, speed, and precision. The system can be fine-tuned by adjusting the input device’s rotational speed, changing the pitch of the screw, or incorporating gearing mechanisms for increased mechanical advantage. This adjustability allows for optimization based on the specific operational requirements, ensuring that the screw jack system performs effectively within the desired parameters.

- Control and Feedback: Screw jacks can be equipped with control systems and feedback mechanisms to enhance load, speed, and precision management. These systems can include motor controllers, position sensors, limit switches, or even automation interfaces. By integrating such control and feedback mechanisms, the screw jack system can be monitored, adjusted, and actively controlled to handle variations in load, speed, and precision more effectively.

In summary, screw jacks handle variations in load, speed, and precision through their design features, adjustability, and the incorporation of control systems. By selecting the appropriate screw jack and considering factors such as load capacity, speed requirements, precision needs, and control mechanisms, variations in load, speed, and precision can be accommodated to meet the specific operational demands of the application.

editor by CX 2024-03-14

China Good quality Nylon Making Screw and Barrel Twin Screw Extruder Machine arrow shaft screw

Product Description

Overview

Product Description

Screw elements are crucial components in twin screw extruders, playing a pivotal role in determining the quality and output of plastic products. These elements are responsible for various essential functions, including plastic molecular mixing, cutting, spreading, and facilitating reactions among the materials. To ensure exceptional production quality, our company has leveraged years of experience, incorporated valuable insights from international practices, and carefully considered customer requirements to develop a comprehensive range of processing screw elements

our meticulously designed screw elements offer a multitude of benefits, prominently featuring exceptional self-cleaning performance. This remarkable attribute guarantees the integrity of the entire production line. Furthermore, our screw elements boast a combination of superior characteristics, including optimum parameters, high self-cleaning efficiency, remarkable wear resistance, and outstanding corrosion resistance.

Through the thoughtful integration of our expertise and customer feedback, we have successfully created a refined selection of screw elements that not only meet but exceed industry standards. These elements ensure the highest quality and output for plastic products, empowering our clients to achieve superior results in their operations.

Screw for Plastic Extruder

1.All sizes of the screw are 38CrMnAlA Nitrided steel +Special Alloy Spraying Welding on the whole screw thread surface.

2. For twin screw barrel material: A. Integral barrel Standard Alloy spraying B. Two parts Bimetallic sleeve C. High Calcium filler abrasion resistant .

3. For single screw barrel: Main Barrel + feeding sleeve zone as basic structure with A type as standard, A: Integral barrel Standard Alloy spraying B:Two parts Bimetallic sleeve .

Basic Info.

| Place of Origin: ZheJiang , China | Brand Name: Arrow |

| Condition: New | Material: 40CrNiMoA |

| Weight (KG): 50 | Spare Parts Type: Barrel |

| Video outgoing-inspection: Provided |

Machinery Test Report: Provided |

| Warranty:1 year | Key Selling Points: Sustainable |

| Applicable Industries: Manufacturing Plant, Machinery Repair Shops |

Item: Bi-metal screw and barrel |

| Material for screw: 38CrMnAlA Nitrided steel |

Material for barrel: 40CrNiMoA+SKDII with heat treatment |

| Screw finish: Nitrogen-filled (0.50~0.70mm depth) |

Core of the screw: Auto control for temperature |

| Screw type: Single/ Double |

Rotate speed of screw: 0-48 |

| Double screw type: Conical/Parallel |

Barrel design for double screw: One body/two parts |

Application:

-For wear application:

Tool Steel: W6Mo5Cr4V2

PM-HIP material: WR5, WR13, WR14, CPM10V, CPM9V.

-For corrosion application:

38CrMoAla

PM-HIP material: WR4, WR13, WR14, CPM10V, CPM9V.

-For wear and corrosion application:

PM-HIP material: WR13, WR14, CPM10V, CPM9V.

-Other materials:

Stainless Steel:316L,440C etc.

Key Features:

- Tool steel, the steel has a high hardenability and thermal cracking resistance, the steel contains a higher content of tungsten, molybdenum,chromium and alum, good wear resistance, toughness is relatively weakened, with good heat resistance.

- High hardness,

- HRC up to 65.

Service

| 24-hour Hotline No matter when and where you are, call us and we can find our service to you. |

Pre-sales Consultation We have 5 sales people online, and whether you have any question can be solved through online communication, and welcome to your consultation. |

After-sales Services

you can receive products to our company and we will help |

FAQ

How long does it take to get my products since I paid for them?

—According to your order, we will give you a reasonable delivery date.

How is your after-sale service?

—You will get our help in time as long as you find something wrong about our produces. Believe us, you deserve the best.

What machine does the product apply to?

—Twin Screw Extruder Machine.

Certification

Exhibition

Company Profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online 24/7 Installation Guide |

|---|---|

| Warranty: | 1 Year |

| Standard: | GB, JIS |

| Samples: |

US$ 99999/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do screw jacks contribute to the safety of tasks like vehicle maintenance?

Screw jacks play a crucial role in ensuring the safety of tasks like vehicle maintenance. They provide stability, lifting capabilities, and precise control, which are essential for safe and efficient maintenance operations. Here’s how screw jacks contribute to safety in vehicle maintenance:

- Stability and Load Capacity: Screw jacks are designed to provide high stability and support heavy loads. When used in vehicle maintenance, they offer a solid and secure platform for lifting and supporting the vehicle. This stability ensures that the vehicle remains steady during maintenance tasks, reducing the risk of accidents or injuries caused by uncontrolled movement or instability.

- Precise Height Adjustment: Screw jacks allow for precise height adjustment, enabling mechanics to position the vehicle at the desired working height. This precise control ensures that the vehicle is at an optimal height for accessing various components, performing inspections, or conducting repairs. It helps maintain a comfortable working posture for mechanics, minimizing the risk of strain or injury.

- Locking Mechanisms: Screw jacks often incorporate locking mechanisms to securely hold the lifted load in position. These locking mechanisms prevent accidental lowering of the vehicle during maintenance tasks, providing an additional layer of safety. Even in the event of power loss or system failure, the locking mechanism ensures that the vehicle remains elevated, reducing the risk of injury or damage.

- Even Weight Distribution: When multiple screw jacks are used in a synchronized system, they distribute the load evenly, ensuring balanced support. This even weight distribution minimizes stress on individual components and prevents overloading, reducing the risk of equipment failure or accidents caused by imbalanced loads.

- Integration with Safety Systems: Screw jacks can be integrated with safety systems to enhance overall safety during vehicle maintenance tasks. For example, limit switches or proximity sensors can be used to prevent the screw jacks from exceeding their maximum or minimum height limits. Emergency stop buttons or safety interlocks can be integrated into the control system, allowing immediate halting of the lifting operation in case of emergencies or hazardous situations.

The combination of stability, precise control, locking mechanisms, even weight distribution, and integration with safety systems makes screw jacks a reliable and safe solution for vehicle maintenance tasks. They provide mechanics with a secure working platform, reduce the risk of accidents, and contribute to the overall safety and efficiency of vehicle maintenance operations.

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

What benefits do screw jacks offer for lifting heavy loads or adjusting height?

Screw jacks offer several benefits for lifting heavy loads or adjusting height in various applications. Here are the key benefits of using screw jacks:

- High Load Capacity: Screw jacks are designed to handle heavy loads. They can provide substantial lifting capacities and are capable of lifting loads ranging from a few kilograms to several tons. The robust construction and mechanical advantage of screw jacks allow for efficient lifting and support of heavy loads.

- Precise Positioning: Screw jacks enable precise positioning of loads or height adjustment. The linear displacement achieved per rotation of the screw can be accurately controlled. This precision is beneficial in applications where precise height adjustment or load positioning is required, such as in manufacturing processes, stage setups, or equipment installations.

- Stability and Safety: Screw jacks provide stability and ensure the safety of lifted or supported loads. Once the desired height or position is reached, the self-locking nature of the screw and nut interface helps maintain the load in position without the need for continuous power or external braking mechanisms. This inherent stability reduces the risk of accidental load movement or slippage, promoting a safe working environment.

- Mechanical Advantage: Screw jacks offer a mechanical advantage due to the pitch of the screw. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased. This allows for the lifting or lowering of heavier loads with relatively less rotational effort. The mechanical advantage provided by screw jacks can significantly reduce the required input force or power.

- Flexible Mounting Options: Screw jacks can be mounted in various configurations to suit different applications. They can be vertically mounted for lifting or adjusting height, horizontally mounted for pushing or pulling loads, or even mounted at an angle to accommodate specific requirements. This flexibility in mounting options makes screw jacks versatile and adaptable to different lifting or positioning scenarios.

- Durability and Reliability: Screw jacks are typically constructed using robust materials such as steel or cast iron, ensuring durability and long-term reliability. They are designed to withstand heavy loads, harsh environments, and frequent use. Proper maintenance and lubrication can further enhance their lifespan and performance.

- Cost-Effective Solution: Screw jacks offer a cost-effective solution for lifting heavy loads or adjusting height compared to other alternatives such as hydraulic or pneumatic systems. They have lower installation and maintenance costs, require less complex infrastructure, and can operate without the need for additional power sources or fluid systems.

In summary, screw jacks offer benefits such as high load capacity, precise positioning, stability and safety, mechanical advantage, flexible mounting options, durability and reliability, and cost-effectiveness. These advantages make screw jacks a popular choice for applications that involve lifting heavy loads or adjusting height with precision and control.

editor by CX 2024-03-11

China Custom Jsw Tex 165 All Shaft for Extruder ball screw shaft coupling

Product Description

We manufacture screw and kneading segments for co-rotating twin screw extruders ranging from 20 mm to 350 mm and over. Our manufacturing specializes in segmented screws for twin screw extruders and is optimized for flexible order handling.

Co-rotating twin screw elements for

-APV -KOBE -OMC

-Buhler -KraussMaffei -Theysohn

-Buss -Berstorff- -Toshiba

-Clextral -Labtech -USEON

-Lantai – others

-JSW -Leistritz

-Keya -Maris

Types of the shaft

* Single Keyway * Square Keyslot *High torque key button * Dual keyslot

* Involute inner spline * Round keyslot *Retackle spline * Client’s requirements available

We offer a broader choice of materials:

For wear application:

* Tool Steel : W6Mo5Cr4V2;

* PM-HIP material : SAM10 , SAM26 , SAM39 ,CPM10V,CPM9V

For corrision application:

* Nitrided Steel: 38CrMoAI;

* PM-HIP material : SAM26 , SAM39 ,CPM10V,CPM9V

For wear and corrision application:

* PM-HIP material: SAM26 , SAM39 ,CPM10V,CPM9V

Other materials:

Stainless Steel: 316L,C276 etc.