Product Description

Product Description

Product Description

Product Name: Nonstandard CNC Machining Turning 304 316 Stainless Steel Shafts

Company Name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

Keywords: Shaft, Custom Precision Shaft, Precision Shaft, CNC Parts Screw, Special Screw, Stainless Steel Screws, Screw, Custom Stainless Steel Screw, Stainless Steel Screw Bolts, 316 Stainless Steel Screws, 316L Stainless Steel Screw, 304 Stainless Steel Screw, Screw Stainless Steel 316, Custom Screws Stainless, Stainless Steel Screws, Steel Screw Stainless, Screw Stainless Steel, Head Screw Stainless, 316 Steel Screws, Custom Shaft

Attributes: Material: Carbon Steel, Load: Drive Shaft, Stiffness / Rigid Axle

Explore our range of nonstandard CNC machining turning stainless steel shafts. Made from high-quality 304 and 316 stainless steel, these custom precision shafts offer exceptional strength and durability. Perfect for various applications, including drive shafts, these shafts provide stiffness and rigidity. Choose from a wide selection of sizes and designs to meet your specific needs. Trust HangZhou CHINAMFG Hardware Industry Co., Ltd. for reliable and precise CNC parts.

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, AL6082-T6 etc. |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H58,H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc. |

Nonstandard CNC Machining Turning Stainless Steel Shafts

Nonstandard CNC Machining Turning Stainless Steel Shafts

Looking for custom precision shafts? Our stainless steel screws are made from high-quality 304 and 316 stainless steel. With a rigid axle and excellent stiffness, these shafts are perfect for drive shaft applications. Order your custom shafts today!

Company name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc plating | Nickel plating |

| Color Anodized | Passivating | Nickel plating | chrome plating |

| Sandblast Anodized | Sandblasting | Chrome plating | Electrophoresis black |

| Polishing | Laser engraving | Oxide black | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Chroming | Oxide black | Heat treatment | |

| Chemical Film | Powder Coated |

Company Profile

CHINAMFG Hardware – Precision CNC Spare Parts

JIESHENG Hardware – Precision CNC Spare Parts

JIESHENG Hardware, a leading manufacturer in the industry, specializes in the production of precision CNC lathes, automatic lathe parts, precision non-standard parts, rivets and nuts, washers, stamping parts, and more. Our expertise lies in providing high-quality non-standard metal parts to clients in various industries.

Our products are made from a wide range of materials including stainless steel, copper, brass, bronze, iron, aluminum, and various types of steel. This versatility allows us to cater to the specific needs of industries such as electronics, hardware, lighting, toys, sanitary ware, furniture, medical, sports equipment, and more.

Choose CHINAMFG Hardware for precision CNC spare parts that meet the highest standards of quality and reliability. With our extensive range of materials and expertise in non-standard metal parts, we can provide customized solutions for various industries. Trust in our experience and commitment to delivering excellence.

For more information, please visit .

Product Details

Product Description: Brass Insert Sharp Knurl Nuts for Thermoplastics

Product Description: Brass Insert Sharp Knurl Nuts for Thermoplastics

Introducing our high-quality Brass Insert Sharp Knurl Nuts specifically designed for thermoplastics. These nuts are perfect for various applications and offer exceptional performance and durability.

Key Features:

- Available in various sizes to suit your specific requirements

- Made from a wide range of materials including aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc, and more

- Higher quantities may result in better pricing, making it cost-effective for bulk orders

- Choose from a variety of surface treatments such as polishing, anodize, nickel, zinc, tin, chrome, and silver plating

- Designed to provide excellent hardness for enhanced strength and longevity

- Comes with reliable packing term for safe transportation and storage

Product Specifications:

Before requesting a quotation, please provide us with the following information:

- Size drawing (If unavailable, please provide detailed product size and picture)

- Material

- Quantity

- Surface treatment

- Hardness

- Packing Term

If you are interested in brass tubular rivets, please feel free to contact us.

Contact Information:

Contact Person: Alice Lee

Company: HangZhou CHINAMFG Hardware Industry Co., Ltd.

FAQ

Stainless Steel Dowel Pins

Stainless Steel Dowel Pins

Are you in need of stainless steel dowel pins for your manufacturing needs? Look no further! HangZhou CHINAMFG Hardware Industry Co., Ltd. is here to provide you with high-quality dowel pins that meet your requirements.

Features:

- Made from durable stainless steel material

- Precision machined for accurate dimensions

- Available in various sizes and lengths

- Corrosion-resistant for long-lasting performance

Benefits:

- Ensures secure and reliable connections

- Reduces the risk of misalignment

- Increases the strength and stability of assembled parts

- Can withstand high temperatures and harsh environments

Sample Request:

If you would like to request a sample of our stainless steel dowel pins, simply contact us and provide the necessary details. We may require a sample cost, but it will be refunded once you proceed with a mass production order. In special conditions, we also offer free samples.

Lead Time:

The lead time for your order depends on the quantity. Generally, it takes 7-20 days after order confirmation for us to fulfill your requirements.

Urgent Orders:

If you have urgent manufacturing needs, don’t worry! We will do our best to assist you. As we have our own factory, we can be flexible in adjusting our production schedule to accommodate your urgent requests.

Confidentiality:

We understand the importance of keeping your designs confidential. If you require a non-disclosure agreement (NDA), we are more than willing to CHINAMFG it. Rest assured that we will not display or share your designs with anyone.

Company name: HangZhou CHINAMFG Hardware Industry Co., Ltd.

Production Updates:

At HangZhou CHINAMFG Hardware Industry Co., Ltd., we understand that not everyone can visit our factory in person. However, we believe in keeping our valued customers informed about the production process every step of the way.

When you choose our products, we will provide you with a detailed production schedule, ensuring transparency and giving you peace of mind. You will know exactly when each stage of the production process will be completed.

In addition to the production schedule, we will also send you pictures and videos showcasing the machining progress. This way, you can see firsthand the high-quality craftsmanship that goes into each and every product we create.

With HangZhou CHINAMFG Hardware Industry Co., Ltd., you can trust that we will keep you involved and informed throughout the production process, even if you can’t visit our factory in person.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

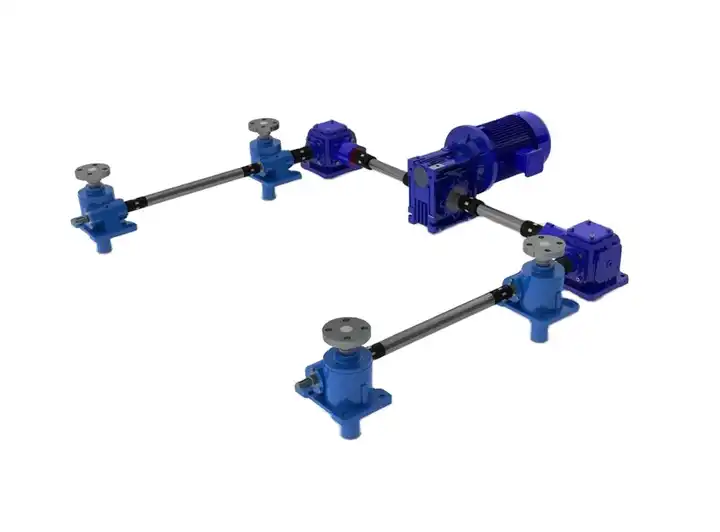

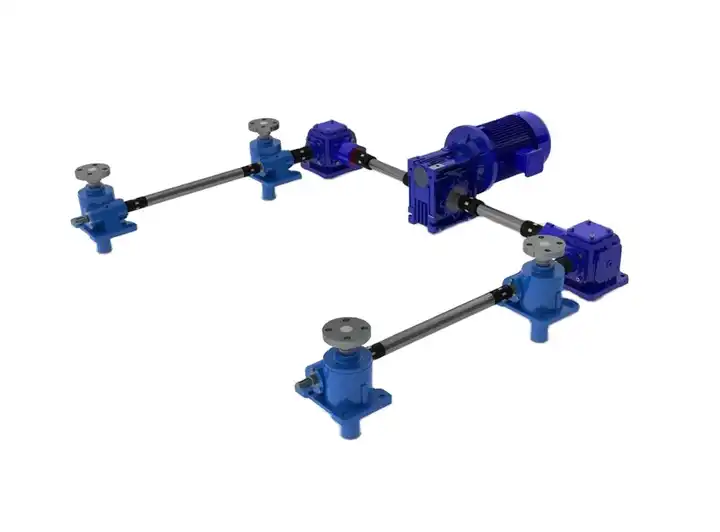

Can screw jacks be integrated with control systems for automation and remote operation?

Yes, screw jacks can be integrated with control systems to enable automation and remote operation. This integration allows for enhanced control, monitoring, and synchronization of multiple screw jacks within a system. Here’s how screw jacks can be integrated with control systems:

- Motorized Screw Jacks: Motorized screw jacks are equipped with electric motors that provide the power required for lifting and adjusting loads. These motorized screw jacks can be integrated with control systems to enable automation and remote operation. The control system can include a programmable logic controller (PLC), human-machine interface (HMI), or a dedicated control unit.

- Communication Protocols: Screw jacks integrated with control systems can use various communication protocols to facilitate remote operation and automation. Common protocols include Modbus, CAN bus, Ethernet/IP, or Profinet. These protocols allow the control system to communicate with the motorized screw jacks, sending commands, receiving feedback, and monitoring their status.

- Position Feedback: Motorized screw jacks integrated with control systems can provide position feedback, allowing the control system to accurately monitor and control the position of the screw jacks. Position sensors, such as encoders or linear potentiometers, can be installed on the screw jacks to provide precise position data to the control system.

- Programming and Sequencing: Control systems can be programmed to execute specific sequences of movements and actions using motorized screw jacks. This programming can include predefined motion profiles, synchronized movements of multiple screw jacks, or customized sequences to meet specific application requirements.

- Remote Operation and Monitoring: Integration with control systems allows for remote operation and monitoring of screw jacks. Through the control system’s interface, operators can remotely control the screw jacks, adjust their positions, monitor their status, and receive real-time feedback on load, position, or any potential issues.

- Integration with Overall Automation Systems: Screw jacks integrated with control systems can be part of larger automation systems, where they work in conjunction with other devices, such as sensors, actuators, or safety systems. This integration enables seamless coordination and synchronization of multiple components to achieve complex automation tasks.

The integration of screw jacks with control systems for automation and remote operation provides numerous benefits, including improved efficiency, precise control, enhanced safety, and the ability to monitor and adjust loads in real-time. This integration is particularly advantageous in applications that require synchronized movement, precise positioning, or remote control of multiple screw jacks within a system.

What are the common signs of wear or issues that might require screw jack maintenance?

Regular maintenance is important for ensuring the proper functioning and longevity of screw jacks. It helps identify and address potential issues before they escalate into more significant problems. Here are some common signs of wear or issues that might indicate the need for screw jack maintenance:

- Unusual Noise: If a screw jack starts producing unusual noises during operation, such as grinding, squeaking, or knocking sounds, it could indicate a problem. These noises may be a result of worn or damaged components, inadequate lubrication, misalignment, or other mechanical issues. Prompt maintenance is necessary to diagnose and resolve the source of the noise.

- Increased Friction: If the movement of the screw jack becomes more difficult or requires excessive force, it could indicate increased friction within the mechanism. This may be caused by insufficient lubrication, contaminated lubricant, or worn components. Addressing the friction issue through maintenance, including lubrication and inspection of components, is important to prevent further damage and ensure smooth operation.

- Excessive Play or Backlash: Excessive play or backlash refers to unwanted movement or looseness in the screw jack assembly. It can occur due to worn or damaged components, improper assembly, or misalignment. Excessive play can negatively impact the precision, stability, and load-bearing capacity of the screw jack. Maintenance should be conducted to identify the cause of the play and rectify it to restore proper functionality.

- Irregular Movement: If the screw jack exhibits irregular or jerky movement instead of smooth and consistent operation, it may indicate issues with the drive mechanism, misalignment, or worn parts. Irregular movement can affect the performance and accuracy of the screw jack, potentially leading to safety hazards or reduced efficiency. Maintenance is necessary to diagnose and address the underlying causes of irregular movement.

- Leakage or Seal Damage: Screw jacks equipped with hydraulic or lubricant-filled systems may experience leakage or seal damage over time. Leakage can result in a loss of lubrication or hydraulic fluid, leading to inadequate lubrication, reduced performance, or system failure. Regular inspection and maintenance of seals, gaskets, and fluid levels are necessary to identify and rectify any leaks or seal damage.

- Visible Wear or Damage: Physical inspection of the screw jack is essential to identify visible signs of wear or damage. This may include worn threads, cracked or damaged housing, bent or misaligned components, or signs of corrosion. Any visible wear or damage should be addressed through maintenance to prevent further deterioration and ensure safe and reliable operation.

Regular inspection and maintenance are crucial to detect and address these signs of wear or issues promptly. It is recommended to follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the optimal performance and longevity of screw jacks.

What factors should be considered when selecting the right screw jack for an application?

When selecting the right screw jack for an application, several factors should be taken into consideration. These factors help ensure that the chosen screw jack meets the specific requirements of the application. Here are the key factors to consider:

- Load Capacity: Determine the maximum load that the screw jack needs to lift or support. Consider both the static load (the weight of the load when stationary) and the dynamic load (additional forces or vibrations that may be present during operation). Select a screw jack with a load capacity that exceeds the application’s requirements to ensure safe and reliable operation.

- Travel Distance: Determine the required travel distance or height adjustment range of the screw jack. Consider both the minimum and maximum travel distances needed for the application. Ensure that the selected screw jack can provide the required travel distance without exceeding its mechanical limits.

- Speed Requirements: Consider the desired operating speed of the screw jack. Determine whether the application requires slow and precise movement or faster operation. The speed of the screw jack is influenced by factors such as the pitch of the screw and the rotational speed of the input device. Select a screw jack that can operate within the desired speed range without compromising other performance factors.

- Precision Needs: Assess the required level of precision for the application. Determine the allowable tolerance and backlash requirements. The precision of a screw jack is influenced by factors such as the pitch of the screw, the quality of the thread, and the presence of additional components such as limit switches or position sensors. Choose a screw jack that can achieve the desired precision level while maintaining stability and load capacity.

- Environmental Conditions: Consider the environmental conditions in which the screw jack will operate. Factors such as temperature, humidity, dust, and corrosive substances can affect the performance and durability of the screw jack. Select a screw jack that is designed to withstand the specific environmental conditions of the application.

- Mounting and Integration: Evaluate the available space for mounting the screw jack and consider the required integration with other components or systems. Determine whether the screw jack needs to be vertically mounted, horizontally mounted, or at an angle. Consider any specific mounting or interface requirements and ensure that the selected screw jack can be easily integrated into the existing system or structure.

- Safety and Compliance: Ensure that the chosen screw jack complies with safety standards and regulations applicable to the specific industry or application. Consider safety features such as self-locking mechanisms, overload protection, and emergency stop options. Verify that the manufacturer or supplier provides adequate documentation and certifications.

- Cost and Budget: Consider the budget and cost-effectiveness of the screw jack. Compare the prices and features of different screw jack models and brands. Evaluate the long-term maintenance and operational costs, including factors such as lubrication requirements and expected lifespan.

By carefully considering these factors, it is possible to select the right screw jack that meets the load capacity, travel distance, speed, precision, environmental, mounting, safety, and budget requirements of the specific application.

editor by Dream 2024-04-24

China Professional Rotor Shaft, Roller Shaft, Rolling Round Shaft Heavy Duty, High Quality with Low Factory Price #8 screw shaft diameter

Product Description

Product Description

Industrial Main Shaft, Axle, Axis, Rod, Plunger, Splindle Process.

Eccentric Axles Shaft, Hollow Shaft/Crankshaft for marine & vessel engine Processing

Camshaft drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

Large Marine Vessel Shaft Package

Spray anti-rust oil on Eccentric Shaft for crusher, Wrap waterproof cloth around Shaft for CZPT crusher, Prepare package by shaft shape & weight to choose steel frame, steel support or wooden box etc.

OEM Customized Eccentric Shaft

We supply OEM SERVICE, customized forging eccentric shaft more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material of Bent Axle .

Detailed Photos

Product Parameters

| Length | L | Range: >1m |

| Weight | Kg | Range: >100kg/ Single Piece |

| Shaft shape | Eccentric Shaft | |

| Material | Forging 30CrMoV9 V 42CrMo/40Cr or Customized | |

| Heat Treatment | Normalizing, Tempering, Induction Harden, etc | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Stone Crusher, Grate Cooler etc | |

| Transport Package | Export package (steel frame, wooden box, etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

CZPT Service

TOTEM Machinery all the time works to supply GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission device & equipment (large industrial reducer & driver). Which mainly use to industrial equipment on fields of port facilities, cement, mining, metallurgical industry etc.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality suppliers’ network, to let customers worry-free purchase.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

About CZPT

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

Contact CZPT

ZheJiang CZPT Machinery Co.,Ltd

Facebook: ZheJiang Totem

FAQ

What’s CZPT product processing progress?

Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

How about TOTEM’s export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material.

Why can I choose TOTEM?

CZPT has 24hrs Salesman on-line, guarantee quick and positive feedback.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier’s network, to let customers worry-free purchase.

Experienced and Professional Forwarder Guarantee Log. transportation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Avaliable |

|---|---|

| Standard: | GB, GOST, ASTM, DIN |

| Surface Treatment: | Normalizing, Tempering, Induction Harden |

| Manufacturing Process: | Forging |

| Material: | Forging |

| Transport Package: | Export Package |

| Customization: |

Available

| Customized Request |

|---|

Can screw jacks be used in conjunction with manual or motorized operation?

Yes, screw jacks can be used in conjunction with both manual and motorized operation, providing flexibility and adaptability to various applications. Screw jacks are versatile devices that can be powered by either human effort or motorized systems. Here’s how screw jacks can be utilized with manual and motorized operation:

- Manual Operation: Screw jacks can be operated manually by applying force to the input shaft or using a handwheel. This manual operation allows for precise control over the lifting or lowering process. It is commonly used in applications where the load is relatively light, adjustments need to be made incrementally, or where power sources may not be readily available. Manual operation provides simplicity, ease of use, and cost-effectiveness.

- Motorized Operation: Screw jacks can also be motorized for automated and efficient operation. Electric motors or hydraulic systems can be integrated with screw jacks to provide power-assisted lifting or lowering. Motorized operation offers advantages such as increased speed, higher lifting capacities, and the ability to handle heavier loads. It is particularly useful in applications where repetitive or frequent adjustments are required, or where large loads need to be lifted or positioned quickly.

- Combination of Manual and Motorized Operation: In certain applications, screw jacks can be used in combination with both manual and motorized operation. This hybrid approach provides the benefits of manual control for fine adjustments and motorized power for heavier lifting or faster operation. For example, a manual handwheel can be used for initial positioning or precise adjustments, while an electric motor can be engaged for larger-scale movements or when power assistance is needed. This combination allows for versatility and adaptability to different load requirements and operating conditions.

The choice between manual and motorized operation depends on factors such as the nature of the application, load requirements, desired speed, available power sources, and operator preferences. Screw jacks offer the flexibility to switch between manual and motorized operation, making them suitable for a wide range of industries and applications, including manufacturing, construction, automotive, and entertainment.

Are there any emerging trends in screw jack technology, such as automation features?

Yes, screw jack technology has been evolving, and there are several emerging trends, including the incorporation of automation features. Here are some notable trends in screw jack technology:

- Motorized Screw Jacks: Motorized screw jacks are becoming increasingly popular. These screw jacks feature integrated electric or hydraulic motors that automate the lifting and leveling process. Motorized screw jacks offer advantages such as increased speed, precise control, and the ability to handle larger loads. They are particularly useful in applications where manual operation may be impractical or when automation is desired for improved efficiency.

- Integrated Control Systems: Screw jacks are now being equipped with integrated control systems that enhance automation. These control systems can include programmable logic controllers (PLCs), human-machine interfaces (HMIs), or other electronic control units. The integration of control systems allows for centralized control, remote operation, and the ability to program complex lifting sequences or preset positions. This automation feature improves efficiency, reduces operator workload, and enhances safety.

- Position Feedback and Monitoring: Another emerging trend in screw jack technology is the incorporation of position feedback and monitoring systems. These systems utilize sensors to provide real-time feedback on the position and movement of the screw jack. By monitoring the position, operators can ensure accurate and precise positioning. Position feedback systems also enable automated control, closed-loop operation, and the ability to detect and respond to any deviations or abnormal conditions during lifting or leveling operations.

- Wireless Connectivity and Industrial IoT: Screw jacks are being integrated into wireless connectivity networks and industrial Internet of Things (IoT) systems. This allows for remote monitoring, data acquisition, and control of screw jacks. Wireless connectivity enables real-time data transmission, remote diagnostics, and predictive maintenance capabilities. By leveraging IoT technologies, screw jacks can be integrated into larger automation systems, enhancing overall operational efficiency and providing valuable insights for maintenance and optimization.

- Improved Materials and Design: Advancements in materials and design are also influencing screw jack technology. Manufacturers are utilizing high-strength materials, such as hardened steel alloys and corrosion-resistant coatings, to enhance the durability, load capacity, and lifespan of screw jacks. Additionally, innovative designs are being implemented to reduce friction, improve efficiency, and minimize wear and tear, resulting in more reliable and efficient screw jack systems.

These emerging trends in screw jack technology, including the incorporation of automation features, are aimed at improving performance, efficiency, and safety in lifting and leveling applications. As technology continues to evolve, we can expect further advancements in screw jack automation and integration with modern industrial systems.

What benefits do screw jacks offer for lifting heavy loads or adjusting height?

Screw jacks offer several benefits for lifting heavy loads or adjusting height in various applications. Here are the key benefits of using screw jacks:

- High Load Capacity: Screw jacks are designed to handle heavy loads. They can provide substantial lifting capacities and are capable of lifting loads ranging from a few kilograms to several tons. The robust construction and mechanical advantage of screw jacks allow for efficient lifting and support of heavy loads.

- Precise Positioning: Screw jacks enable precise positioning of loads or height adjustment. The linear displacement achieved per rotation of the screw can be accurately controlled. This precision is beneficial in applications where precise height adjustment or load positioning is required, such as in manufacturing processes, stage setups, or equipment installations.

- Stability and Safety: Screw jacks provide stability and ensure the safety of lifted or supported loads. Once the desired height or position is reached, the self-locking nature of the screw and nut interface helps maintain the load in position without the need for continuous power or external braking mechanisms. This inherent stability reduces the risk of accidental load movement or slippage, promoting a safe working environment.

- Mechanical Advantage: Screw jacks offer a mechanical advantage due to the pitch of the screw. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased. This allows for the lifting or lowering of heavier loads with relatively less rotational effort. The mechanical advantage provided by screw jacks can significantly reduce the required input force or power.

- Flexible Mounting Options: Screw jacks can be mounted in various configurations to suit different applications. They can be vertically mounted for lifting or adjusting height, horizontally mounted for pushing or pulling loads, or even mounted at an angle to accommodate specific requirements. This flexibility in mounting options makes screw jacks versatile and adaptable to different lifting or positioning scenarios.

- Durability and Reliability: Screw jacks are typically constructed using robust materials such as steel or cast iron, ensuring durability and long-term reliability. They are designed to withstand heavy loads, harsh environments, and frequent use. Proper maintenance and lubrication can further enhance their lifespan and performance.

- Cost-Effective Solution: Screw jacks offer a cost-effective solution for lifting heavy loads or adjusting height compared to other alternatives such as hydraulic or pneumatic systems. They have lower installation and maintenance costs, require less complex infrastructure, and can operate without the need for additional power sources or fluid systems.

In summary, screw jacks offer benefits such as high load capacity, precise positioning, stability and safety, mechanical advantage, flexible mounting options, durability and reliability, and cost-effectiveness. These advantages make screw jacks a popular choice for applications that involve lifting heavy loads or adjusting height with precision and control.

editor by Dream 2024-04-19

China Good quality Factory Price Linear Transmission Bearing Shaft for CNC Machine screw shaft for

Product Description

UP Gold(ZheJiang )Automation Technology Co. Ltd, is a supplier of linear CZPT way, linear rail series,lead screw,block bearing, roller bearing ,ball bearing,pillow block bearing, rod ends bearing ,needle roller bearing,screw bearing ,slider bearings and slewing support bearings and so on.

We have exported more than 100 countries like USA, Mexico,Canada, Spain, Russia,Singapore,Thailand, India etc.We are committed to creating a one-stop shopping platform for customers to save time, improve efficiency with the best price and quality to win the trust of customers. Win-win cooperation is our company’s business philosophy.

Customer Service

*12 Months Warranty *Fast Delivery

*24 hours on line service *Professional Team

Product Description

Linear shafts are metal rods made of C1045 Induction Hardened and Hard Chrome plated.The rods bear rigorous tactics like pilling, straightening, hardening, grinding, polishing, tough chrome plating and ending underneath the supervision of skilled engineers. Different from the Hard Chrome Plated Piston Rods, the floor hardness of the Induction Hardened Chrome Rods is excessive up to HRC58-62 by way of high-frequency induction harden technique. Linear shafts are normally used as information rail or slide rail matching with Linearing Bearings due to the fact of the floor excessive durability, abrasion resistance, longer working lifestyles and dimensional accuracy.

| Product Name |

NYZ Linear Shaft |

| Model Number |

All |

| Size |

Customized |

| Feature |

1. Low Noise; 2.Long Life |

| Precision |

High Precision |

| Material |

Chrome Steel GCr15 |

| Delivery Time | 1) 1-5 Workdays for Samples or in Stock 2) 10-30 Working Days for Ordering |

Customer Comment

Packaging and Logistics

Bearing packaging mode

01 Industrial packaging

Plastic tube + Carton + Pallet

02 Commercial packaging

Plastic bag + Kraft paper+ Carton+ Pallet

03 Original packing+ pallet

| Air freight |

| Less than 45 KGS,we will send by express.(Door to Door, Convenient) |

| Land transportation |

| Between 45- 150 KGS, we will send by air transport. (Fastest and safest, but expesn -sive) |

| Railway |

| More than 150 KGS,we will send by sea. |

| Shipping |

| According to the requirement of customer. |

FAQ

Q: What is the producing process?

A: Production process including raw material cutting, machine processing,grinding, accessories cleaning, assemble, cleaning, stoving, oil coating,cover pressing, testing, package.

Q: How to control the products quality?

A: Combining advanced equipment and strict management, we provide high standard and quality bearings for our customers all over the world.

Q: What is the transportation?

A: If small quantity, we suggest to send by express, such as DHL, UPS,TNT FEDEX. If large amount, by air or sea shipping.

Q: How about the shipping charge?

A: We will be free of domestic shipping charge from your freight forwarder in China.

Q: Can you provide OEM service?

A: Yes, we provide OEM service. Which means size, quantity, design,packing solution, etc will depend on your requests; and your logo will be customized on our products.

Q: Could you tell me the delivery time of your goods?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to the quantity.

Q: What about the packaging of your products?

A: Normally we use standard commercial package, we also have our own brand packing or customized package as per customers’ requests.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do screw jacks ensure controlled and synchronized movement in multi-jack systems?

Screw jacks are capable of ensuring controlled and synchronized movement in multi-jack systems through various mechanisms and techniques. These systems are commonly used in applications where multiple screw jacks need to work together to lift or position a load. Here’s how screw jacks achieve controlled and synchronized movement in multi-jack systems:

- Mechanical Synchronization: Screw jacks can be mechanically linked in a multi-jack system to ensure synchronized movement. This can be achieved through the use of rigid couplings, connecting rods, or gear mechanisms that interconnect the input shafts of individual screw jacks. As a result, when one screw jack is operated to lift or lower the load, the mechanical linkage transfers the motion to the other screw jacks, causing them to move in sync. This ensures that all jacks contribute proportionally to the load and maintain a consistent lifting height.

- Electrical Synchronization: In addition to mechanical synchronization, screw jacks can also be electrically synchronized in multi-jack systems. This is typically achieved through the use of motorized screw jacks controlled by a centralized control system. Each motorized screw jack is equipped with position sensors or encoders that provide feedback on their current position. The control system receives this feedback and adjusts the motor speed and direction for each screw jack to ensure synchronized movement. Electrical synchronization enables precise control and allows for adjustments to be made dynamically, compensating for any variations in load distribution or environmental conditions.

- Load Sharing Mechanisms: In multi-jack systems, load sharing mechanisms can be employed to distribute the weight evenly among the screw jacks. Load sharing mechanisms can include load sensors or load cells that measure the individual loads on each jack. The control system then adjusts the lifting force applied by each screw jack to ensure equal distribution of the load. This prevents overloading of any individual jack and promotes balanced movement in the system.

- Position Feedback and Control: Screw jacks in multi-jack systems can be equipped with position feedback devices, such as linear encoders or limit switches, that provide information on the position of the load. This feedback is used by the control system to precisely control the movement of the screw jacks, ensuring that they reach and maintain the desired positions. By continuously monitoring the position feedback, the control system can make adjustments to keep the jacks synchronized and maintain the desired level of control.

- Control System Integration: A centralized control system can be used to integrate and coordinate the operation of multiple screw jacks in a multi-jack system. This control system can utilize programmable logic controllers (PLCs) or computer numerical control (CNC) systems to manage the movement, synchronization, and safety aspects of the screw jacks. The control system enables precise control, real-time monitoring, and the implementation of safety features, enhancing the overall performance and reliability of the multi-jack system.

By employing these mechanisms and techniques, screw jacks ensure controlled and synchronized movement in multi-jack systems. These systems find applications in various industries, such as heavy lifting, material handling, and industrial automation, where precise positioning and synchronized operation are critical requirements.

Can screw jacks be used for both light-duty and heavy-duty applications?

Yes, screw jacks are versatile mechanical devices that can be used for both light-duty and heavy-duty applications. Their design and construction allow them to handle a wide range of loads, making them suitable for various industrial, commercial, and residential tasks. Here’s how screw jacks are used in both light-duty and heavy-duty applications:

- Light-Duty Applications: Screw jacks find application in numerous light-duty tasks where precise positioning, lifting, or adjustment is required. Examples of light-duty applications include:

- Workbenches and assembly stations: Screw jacks can be employed to adjust the height of workbenches or assembly stations, allowing operators to work at comfortable levels.

- Stage and theater equipment: Screw jacks are used to raise or lower stage platforms, lighting fixtures, or props, allowing for easy setup and adjustments during performances.

- Medical and healthcare equipment: Screw jacks are utilized in medical beds, examination tables, or dental chairs to enable height adjustments for patient comfort and medical procedures.

- Optical and laboratory equipment: Screw jacks provide precise vertical positioning in optical systems, microscopes, or laboratory setups, ensuring accurate alignment and focus.

- Residential applications: Screw jacks can be used in home applications, such as adjustable tables, ergonomic furniture, or lifting mechanisms for storage units.

- Heavy-Duty Applications: Screw jacks are also capable of handling heavy-duty applications that involve substantial loads and demanding conditions. Examples of heavy-duty applications include:

- Industrial machinery: Screw jacks are utilized in various industrial machinery, including presses, injection molding machines, or material handling equipment, to provide precise control and lifting capabilities.

- Construction and infrastructure projects: Screw jacks are employed in construction tasks, such as formwork systems, scaffolding, or temporary structures, for lifting, leveling, or supporting heavy loads.

- Transportation and automotive: Screw jacks find application in automotive lifts, vehicle maintenance equipment, or cargo handling systems, enabling the lifting and positioning of heavy vehicles or loads.

- Shipbuilding and offshore industries: Screw jacks are used in shipbuilding and offshore applications for tasks such as aligning sections, adjusting propeller pitch, or lifting heavy components during construction or maintenance.

- Mining and heavy equipment: Screw jacks are utilized in mining machinery, cranes, or heavy equipment for load positioning, maintenance, or stabilization.

It’s important to note that the specific design, size, and load capacity of the screw jack should be matched to the requirements of the application. Manufacturers provide a wide range of screw jack models with varying load capacities, travel distances, and configurations to accommodate both light-duty and heavy-duty applications. Proper selection and installation of the screw jack ensure optimal performance and safety in diverse tasks.

What benefits do screw jacks offer for lifting heavy loads or adjusting height?

Screw jacks offer several benefits for lifting heavy loads or adjusting height in various applications. Here are the key benefits of using screw jacks:

- High Load Capacity: Screw jacks are designed to handle heavy loads. They can provide substantial lifting capacities and are capable of lifting loads ranging from a few kilograms to several tons. The robust construction and mechanical advantage of screw jacks allow for efficient lifting and support of heavy loads.

- Precise Positioning: Screw jacks enable precise positioning of loads or height adjustment. The linear displacement achieved per rotation of the screw can be accurately controlled. This precision is beneficial in applications where precise height adjustment or load positioning is required, such as in manufacturing processes, stage setups, or equipment installations.

- Stability and Safety: Screw jacks provide stability and ensure the safety of lifted or supported loads. Once the desired height or position is reached, the self-locking nature of the screw and nut interface helps maintain the load in position without the need for continuous power or external braking mechanisms. This inherent stability reduces the risk of accidental load movement or slippage, promoting a safe working environment.

- Mechanical Advantage: Screw jacks offer a mechanical advantage due to the pitch of the screw. By increasing the pitch or using multiple-start threads, the linear displacement achieved per rotation can be increased. This allows for the lifting or lowering of heavier loads with relatively less rotational effort. The mechanical advantage provided by screw jacks can significantly reduce the required input force or power.

- Flexible Mounting Options: Screw jacks can be mounted in various configurations to suit different applications. They can be vertically mounted for lifting or adjusting height, horizontally mounted for pushing or pulling loads, or even mounted at an angle to accommodate specific requirements. This flexibility in mounting options makes screw jacks versatile and adaptable to different lifting or positioning scenarios.

- Durability and Reliability: Screw jacks are typically constructed using robust materials such as steel or cast iron, ensuring durability and long-term reliability. They are designed to withstand heavy loads, harsh environments, and frequent use. Proper maintenance and lubrication can further enhance their lifespan and performance.

- Cost-Effective Solution: Screw jacks offer a cost-effective solution for lifting heavy loads or adjusting height compared to other alternatives such as hydraulic or pneumatic systems. They have lower installation and maintenance costs, require less complex infrastructure, and can operate without the need for additional power sources or fluid systems.

In summary, screw jacks offer benefits such as high load capacity, precise positioning, stability and safety, mechanical advantage, flexible mounting options, durability and reliability, and cost-effectiveness. These advantages make screw jacks a popular choice for applications that involve lifting heavy loads or adjusting height with precision and control.

editor by CX 2024-04-16

China Custom Top Quality Good Resistance High Temperature Inconel 718 Bar Hasteloy C276 Rod Shaft Price Per Kg screw adjustable axle stands

Product Description

Special-Shaped Titanium Ti Evaporation Crucible Factory

Product Description

Here are some products that can be made using MIM (Metal Injection Molding) process:

1. Medical implants and devices, such as bone screws, dental implants, and surgical instruments.

2. Firearms components, including triggers, hammers, and other small parts.

3. Aerospace and defense parts, such as gears, brackets, and housings.

4. Electronics components, including connectors, switches, and small gears.

5. Automotive components, including engine components, brake system components, and suspension parts.

6. Jewelry components, including clasps, bezels, and decorative elements.

7. Consumer goods parts, such as eyeglass frames, watch components, and small gadgets.

8. Industrial tool parts, including inserts, blades, and cutting tools.

9. Musical instrument components, such as guitar parts and trumpet valves.

10. Sporting equipment components, including golf club heads, fishing reel parts, and bike components.

These are just a few examples of the many products that can be made using the MIM process. With its ability to produce complex geometries and high-quality finishes, MIM is an ideal manufacturing process for a wide range of industries and applications.

MIM Parts Tolerance

The tolerances for MIM (Metal Injection Molding) parts are typically very close and precise. In general, tolerances for MIM parts can be as tight as +/- 0.5% of the dimension, or +/- 0.005 inches (0.127 mm), whichever is greater. However, the specific tolerance requirements will depend on the application and the design of the part.

The MIM process is capable of producing complex shapes with high accuracy and repeatability, making it possible to achieve very tight tolerances. Additionally, the material properties of MIM parts are highly consistent, which further contributes to the precision and consistency of the final product.

It’s important to note that achieving tight tolerances may require additional steps, such as post-processing or secondary operations, to ensure that the parts meet the required specifications. Additionally, the cost of producing parts with tight tolerances can be higher due to the additional time and effort required to achieve them.

MIM Parts Advantage

1. Complex geometries: MIM can produce complex shapes and geometries that are difficult or even impossible to achieve with traditional manufacturing methods. This enables designers to create parts with intricate features and high functionality.

2. High precision: The MIM process can achieve very tight tolerances, making it possible to produce parts with high accuracy and consistency.

3. Excellent surface finish: MIM parts have a high-quality surface finish, which eliminates the need for additional finishing operations.

4. Versatility: MIM can produce parts from a range of materials, including stainless steel, low alloy steels, tool steels, titanium alloys, and more. This makes it possible to create parts with a wide range of mechanical properties and applications.

5. Cost-effective: MIM is a cost-effective manufacturing process, especially for small to medium-scale production runs. It can eliminate the need for multiple manufacturing steps and reduce material waste, resulting in lower overall costs.

Overall, MIM parts offer a range of benefits for manufacturers and customers alike, including the ability to create complex geometries, high precision, excellent surface finishes, versatility, and cost-effectiveness.

Detailed Photos

The MIM Process

the MIM (Metal Injection Molding) process can be broken down into several steps:

1. Formulation: The first step in the MIM process is to formulate the feedstock. This typically involves mixing a fine metal powder with a thermoplastic binder material and sometimes a lubricant. The binder material helps to hold the metal particles together and enables them to flow like plastic.

2. Injection molding: The feedstock is then injected into a mold cavity using an injection molding machine. The mold is typically made from steel or other durable materials and is designed to produce the desired shape of the final part.

3. Debinding: Once the part has been molded, it is subjected to a debinding process, which removes the binder material from the metal particles. This is typically done by heating the part in a CZPT or using a solvent.

4. Sintering: After debinding, the part is subjected to a high-temperature sintering process. This process fuses the metal particles together, forming a CHINAMFG metal part with the desired mechanical properties. The sintering process can take several hours to complete, depending on the size and complexity of the part.

5. Finishing: After sintering, the final part may undergo additional finishing operations, such as polishing, machining, or plating, to achieve the desired surface finish and tolerances.

Overall, the MIM process is a highly versatile and precise manufacturing method that is capable of producing complex metal parts with high accuracy and consistency. It is often used in industries such as medical devices, firearms, aerospace, electronics, and automotive, where precision, complexity, and cost-effectiveness are key considerations.

Product Parameters

The Material of the MIM Product

| Material System | Material Composition | Typical Applications |

| Low Alloy Steel | Fe-2Ni , Fe-8Ni | Automobile, machinery, and other industries, particularly in structural parts |

| Stainless Steel | 316L,17-4PH,420,440C | Medical equipment, clocks, watches |

| Carbide | WC-Co | Various tools, clocks, watches |

| Ceramic | Al2O3 ,ZrO2 ,SiO2 | IT electronics, daily necessities, watches |

| Heavy Alloys | W-Ni-Fe,W-Ni-Cu,W-Cu | The arms industry, communications, daily necessities |

| Titanium | Ti,Ti-6Al-4V | Medical and Firearm structural parts |

| Magnetic Materials | Fe, NdFeB,SmCo5, Fe-Si | Magnetic properties of the various components |

| Tool Steel | CrMo4,M2 | Tools |

Typical properties of several MIM materials

| Materials | Density | Hardness | Tensile Strength | Elongation | |

| g/cm³ | Rockwell | Mpa | % | ||

| Fe-based alloys | MIM-2200(Sintered) | 7.65 | 45HRB | 290 | 40 |

| MIM-2700(Sintered) | 7.65 | 69HRB | 440 | 26 | |

| MIM-4605(Sintered) | 7.62 | 62HRB | 415 | 15 | |

| MIM-4605(Quenching and tempering) | 7.62 | 48HRC | 1655 | 2 | |

| Stainless steel | MIM-316L(Sintered) | 7.92 | 67HB | 520 | 50 |

| MIM-17-4PH(Sintered) | 7.5 | 27HRC | 900 | 6 | |

| MIM-17-4PH(Sintered) | 7.5 | 40HRC | 1185 | 6 | |

| MIM-430L(Sintered) | 7.5 | 65HRB | 415 | 25 | |

| Tungsten alloys | 95%W-Ni-Fe | 18.1 | 30 | 960 | 25 |

| 97%W-Ni-Fe | 18.5 | 33 | 940 | 15 | |

| Carbide | YG8X | 14.9 | HRA90 | Bending Strength 2300 | |

| Fine Ceramics | Al2O3 | 3.98 | HRA92 | Bending Strength 2300 | |

Packaging & Shipping

- We prefer DHL or TNT express or other air freight between 1kg-100kg.

- we choose sea freight of more than 100kg or more than 1CBM

- As per customized specifications.

Company Profile

About us

HangZhou CHINAMFG Technology Co., Ltd has been an established manufacturer since 2008. It is located in HangZhou City, ZheJiang Province, which is close to ZheJiang . The CHINAMFG Technology is fully equipped with all kinds of metal injection molding equipment and Powder Metallurgy equipment.

We specialize in tooling design and product development. We can work with materials such as low alloy steel, stainless steel, tool steel, and titanium steel. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics, and Medical. As 1 of the leading suppliers of metal parts in China, we offer high-quality, custom, precision parts at competitive prices according to customer drawings and specifications.

Our advantage in the industrial market is that we can provide competitive prices for our customers. We have a completely competitive metal parts provider and supply chain solution. With a strong focus on continual improvement, we only utilize best practices to ensure that the work we do for our customers is done in the most efficient, precise, and cost-effective way possible.

The focus of Machining Design Associated has been and always will be on developing and maintaining lasting relationships with customers. We are proud to be large enough to handle our customer needs yet small enough to offer the personal attention customers appreciate.

We have full OEM Experience worldwide, providing them with One-stop solutions for a broad range of applications. We believe in quality and on-time delivery is our corn idea in order to meet our customers’ requirements.

We look CHINAMFG to cooperating with you!

Our Advantages

Why Choice Emitech as your MIM parts supplier, there may be several reasons why they could be a good choice:

1. Experience: CHINAMFG may have significant experience in the MIM industry, with a proven track record of producing high-quality parts for various applications.

2. Precision: CHINAMFG may use advanced technology and equipment to manufacture MIM parts with tight tolerances and high precision, ensuring consistent quality.

3. Customization: CHINAMFG may work closely with its customers to develop customized MIM parts that meet specific requirements and specifications.

4. Material Variety: CHINAMFG may offer a wide range of material options for MIM, including stainless steel, low alloy steels, tool steels, titanium alloys, and more, enabling their customers to choose the best material for their applications.

5. Cost-effectiveness: CHINAMFG may offer competitive pricing for their MIM parts, making it a cost-effective option for small to medium-scale production runs.

If CHINAMFG meets your specific needs and requirements, they may be a good choice for your MIM parts supplier, based on factors such as experience, precision, customization, material variety, and cost-effectiveness.

After Sales Service

Factory Supply High Demand aluminum machining parts factory

We usually provide 12 Months of repair service. If our duty, we will respond to send the new parts.

Our Service

| Our Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, and CIF, As per the customer’s request |

| Shipment Terms |

1)We prefer DHL, TNT express, or other air freight between 1kg-100kg. 2) we prefer sea freight of more than 100kg or more than 1CBM |

| Note | The CNC machining parts are usually custom-made based on the customer’s drawings and samples. So we need the Down Payment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Repaire |

|---|---|

| Warranty: | Half a Year |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do screw jacks play in the precision of assembly line operations?

Screw jacks play a crucial role in ensuring the precision of assembly line operations. They are widely used in manufacturing and assembly processes where accurate positioning, alignment, and control are essential. Here’s how screw jacks contribute to the precision of assembly line operations:

- Precise Positioning: Screw jacks provide precise and controlled linear motion, allowing for accurate positioning of components, parts, or tools on the assembly line. The screw mechanism of the screw jack enables fine adjustments with high positional accuracy, ensuring that each component is correctly placed and aligned according to the required specifications.

- Height Adjustment: Screw jacks are commonly used for height adjustment applications in assembly lines. They allow for easy and precise vertical movement, enabling operators to align workstations, fixtures, or equipment at the optimal height for efficient assembly operations. The ability to fine-tune the height with screw jacks ensures ergonomic working conditions and promotes worker comfort and productivity.

- Load Handling: Screw jacks have the capability to handle a wide range of loads, from light to heavy. This makes them suitable for assembly line operations that involve different types of components or equipment with varying weights. By providing reliable load support and stability, screw jacks contribute to the precision of assembly line operations by ensuring that the load is properly supported and aligned during the assembly process.

- Force Control: Screw jacks offer precise force control capabilities, allowing operators to apply consistent and controlled forces during assembly operations. This is particularly important for tasks that require delicate handling or specific force requirements, such as tightening bolts, fastening components, or applying pressure for proper fitment. The force control provided by screw jacks helps maintain the required precision and avoids overloading or damaging the assembly components.

- Synchronization: In assembly line operations that involve multiple workstations or moving parts, screw jacks can be synchronized to ensure coordinated movement. By mechanically or electrically linking the screw jacks together, they can

What safety precautions should be followed when operating screw jacks?

Operating screw jacks safely is essential to prevent accidents, injuries, and damage to equipment. Here are some important safety precautions that should be followed when operating screw jacks:

- Read and Understand the Manual: Before operating a screw jack, carefully read and understand the manufacturer’s instruction manual. The manual provides important safety information, operating procedures, and maintenance guidelines specific to the screw jack model. Following the manufacturer’s instructions is crucial for safe and proper operation.

- Inspect the Screw Jack: Prior to use, inspect the screw jack for any signs of damage, wear, or loose components. Check for proper lubrication and ensure that all connections and fasteners are secure. If any issues are identified, do not operate the screw jack and address the problems through maintenance or contact the manufacturer for assistance.

- Use Appropriate Personal Protective Equipment (PPE): When operating a screw jack, wear the necessary personal protective equipment (PPE) as recommended by the manufacturer and applicable safety regulations. This may include safety glasses, gloves, steel-toed shoes, or other protective gear depending on the specific application and work environment.

- Ensure Stable Support: Place the screw jack on a stable and level surface capable of supporting the load. Ensure that the supporting structure or surface is capable of withstanding the forces generated during the lifting or lowering operation. Use appropriate blocking or shoring if additional support is required.

- Do Not Exceed Load Capacity: Never exceed the load capacity specified by the manufacturer for the screw jack. Overloading the screw jack can lead to instability, component failure, or other safety hazards. It is important to know the weight of the load being lifted or supported and select a screw jack with an appropriate load rating.

- Operate Smoothly and Carefully: Operate the screw jack smoothly and carefully, avoiding sudden or jerky movements. Use the operating handle or control mechanism provided by the manufacturer and follow the recommended operating procedures. Maintain control over the lifting or lowering process, and ensure that personnel or body parts are clear of pinch points or potential hazards.

- Do Not Use as a Permanent Support: Screw jacks are not designed to be used as permanent supports or to sustain constant loads over extended periods. They are intended for intermittent or temporary use. Avoid using screw jacks as permanent supports or in situations where prolonged load-bearing is required.

- Properly Store and Maintain: After use, properly store the screw jack in a clean and dry environment. Follow the manufacturer’s maintenance guidelines for lubrication, inspection, and periodic maintenance. Regularly check the screw jack for any signs of wear, damage, or deterioration, and address any issues promptly.

- Training and Competence: Ensure that operators are adequately trained and competent in the safe operation of screw jacks. Training should cover proper use, maintenance, and understanding of the associated hazards and safety precautions.

Following these safety precautions when operating screw jacks promotes a safe working environment and helps prevent accidents or injuries. It is important to prioritize safety and adhere to the manufacturer’s guidelines and industry best practices.

How do screw jacks ensure stable and controlled movement of loads?

Screw jacks are designed to ensure stable and controlled movement of loads through various mechanisms and features. These mechanisms work together to provide stability, precision, and safety during load handling. Here’s how screw jacks achieve stable and controlled movement:

- Self-Locking Mechanism: Screw jacks are equipped with self-locking mechanisms that prevent the load from lowering or descending when the screw is not being rotated. This mechanism ensures that the load remains stable and stationary even in the absence of an external driving force. The self-locking feature is achieved through the thread design and the friction between the screw and the nut. It provides inherent stability and eliminates the need for additional braking or locking mechanisms.

- High Mechanical Advantage: Screw jacks offer a high mechanical advantage, allowing for controlled movement of heavy loads with relatively low input force. The mechanical advantage is determined by the pitch of the screw and the size of the input device. By increasing the pitch or using a larger input device, the mechanical advantage can be enhanced, enabling precise and controlled movement even with substantial loads.

- Precision Thread Design: The threads of the screw and the nut in screw jacks are precision-designed to minimize backlash and play, ensuring smooth and accurate movement. The thread design influences the amount of axial movement achieved per rotation of the screw, directly impacting the precision of load positioning. By using high-quality threads and incorporating anti-backlash features, screw jacks maintain stability and control during load movement.

- Limit Switches and Position Sensors: Screw jacks can be equipped with limit switches or position sensors to provide accurate position feedback and prevent overtravel or exceedance of specified limits. These devices ensure that the load stops at the desired position and prevent any unsafe or unintended movement. Limit switches and position sensors enhance the control and safety of screw jack systems.

- Additional Safety Features: Screw jacks may incorporate additional safety features to ensure stable and controlled movement. These features can include overload protection mechanisms that prevent excessive loads from damaging the screw jack or the load-bearing structure. Emergency stop options or mechanical brakes may also be included to halt the movement in case of emergencies or power failure.

- Sturdy Construction: Screw jacks are built with robust materials and construction to withstand heavy loads and provide stability during operation. The components are designed to handle the forces exerted during load movement and maintain structural integrity. Sturdy construction ensures that the screw jack can reliably handle the load without compromising stability or control.

By incorporating self-locking mechanisms, high mechanical advantage, precision thread design, limit switches, position sensors, additional safety features, and sturdy construction, screw jacks ensure stable and controlled movement of loads. These features work together to provide precise positioning, prevent unintended movement, and enhance the safety of load handling operations.

editor by CX 2024-03-07

China OEM Good Price Sfc25 CNC Linear Optical Shaft for Crane screw and axle

Product Description

Company Profile

UP GOLD Automation Technology Co., LTD., independent brand, NYZ and UP. The main products are linear CZPT rail, slider, ball screw, linear optical shaft, linear bearing, machine tool spindle special P4 high precision bearings and accessories, with advanced production equipment and testing instruments to ensure the accuracy of each product. Precision products will provide higher value to the equipment. The company promises to sell each product, warranty period of 24 months, 24 hours after-sales service. Provide professional OEM cooperation model. At the same time, the company agents international first-line brands HIWIN, TBI, NSK,THK. Sufficient resources to ensure every customer needs.

Our Advantages

*Two-year warranty, replace instead of repair.

*12 Months Warranty

*Fast Delivery

*24 hours on line service

*Professional Team

Product Description

Linear shafts are metal rods made of C1045 Induction Hardened and Hard Chrome plated.The rods bear rigorous tactics like pilling, straightening, hardening, grinding, polishing, tough chrome plating and ending underneath the supervision of skilled engineers. Different from the Hard Chrome Plated Piston Rods, the floor hardness of the Induction Hardened Chrome Rods is excessive up to HRC58-62 by way of high-frequency induction harden technique. Linear shafts are normally used as information rail or slide rail matching with Linearing Bearings due to the fact of the floor excessive durability, abrasion resistance, longer working lifestyles and dimensional accuracy.

| Product Name |

Good Price SFC25 CNC Linear Optical Shaft for Engraving Machinery |

| Model Number |

SFC25 |

| Size |

1m |

| Feature |

1.High performance 2.High rigidity 3.High power 5.Easy maintenance |

| Precision |

High Precision |

| Material |

Chrome Steel GCr15 |

| Delivery Time |

1) 1-5 Workdays for Samples or in Stock 2) 10-30 Working Days for Ordering |

Customer Comment

Packaging & Shipping

Bearing packaging mode

01 Industrial packaging

Plastic tube + Carton + Pallet

02 Commercial packaging

Plastic bag + Kraft paper+ Carton+ Pallet

03 Original packing+ pallet

Mode Of Transportation

Air freight

Less than 45 KGS,we will send by express.

(Door to Door,Convenient)

Land transportation

Between 45- 150 KGS, we will send by air transport.

(Fastest and safest, but expensive)

Railway

More than 150 KGS,we will send by sea.

Shipping

According to the requirement of customer.

FAQ

Q: What is the producing process?

A: Production process including raw material cutting, machine processing,grinding, accessories cleaning, assemble, cleaning, oil coating,cover pressing, testing, package.

Q: How to control the products quality?

A: Combining advanced equipment and strict management, we provide high standard and quality bearings for our customers all over the world.

Q: What is the transportation?

A: If small quantity, we suggest to send by express, such as DHL, UPS,TNT FEDEX. If large amount, by air or sea shipping.

Q: How about the shipping charge?

A: We will be free of domestic shipping charge from your freight forwarder in China.

Q: Can you provide OEM service?

A: Yes, we provide OEM service. Which means size, quantity, design,packing solution, etc will depend on your requests; and your logo will be customized on our products.

Q: Could you tell me the delivery time of your goods?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to the quantity.

Q: What about the packaging of your products?

A: Normally we use standard commercial package, we also have our own brand packing or customized package as per customers’ requests.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can screw jacks be integrated with control systems for automation and remote operation?

Yes, screw jacks can be integrated with control systems to enable automation and remote operation. This integration allows for enhanced control, monitoring, and synchronization of multiple screw jacks within a system. Here’s how screw jacks can be integrated with control systems:

- Motorized Screw Jacks: Motorized screw jacks are equipped with electric motors that provide the power required for lifting and adjusting loads. These motorized screw jacks can be integrated with control systems to enable automation and remote operation. The control system can include a programmable logic controller (PLC), human-machine interface (HMI), or a dedicated control unit.

- Communication Protocols: Screw jacks integrated with control systems can use various communication protocols to facilitate remote operation and automation. Common protocols include Modbus, CAN bus, Ethernet/IP, or Profinet. These protocols allow the control system to communicate with the motorized screw jacks, sending commands, receiving feedback, and monitoring their status.

- Position Feedback: Motorized screw jacks integrated with control systems can provide position feedback, allowing the control system to accurately monitor and control the position of the screw jacks. Position sensors, such as encoders or linear potentiometers, can be installed on the screw jacks to provide precise position data to the control system.

- Programming and Sequencing: Control systems can be programmed to execute specific sequences of movements and actions using motorized screw jacks. This programming can include predefined motion profiles, synchronized movements of multiple screw jacks, or customized sequences to meet specific application requirements.

- Remote Operation and Monitoring: Integration with control systems allows for remote operation and monitoring of screw jacks. Through the control system’s interface, operators can remotely control the screw jacks, adjust their positions, monitor their status, and receive real-time feedback on load, position, or any potential issues.

- Integration with Overall Automation Systems: Screw jacks integrated with control systems can be part of larger automation systems, where they work in conjunction with other devices, such as sensors, actuators, or safety systems. This integration enables seamless coordination and synchronization of multiple components to achieve complex automation tasks.

The integration of screw jacks with control systems for automation and remote operation provides numerous benefits, including improved efficiency, precise control, enhanced safety, and the ability to monitor and adjust loads in real-time. This integration is particularly advantageous in applications that require synchronized movement, precise positioning, or remote control of multiple screw jacks within a system.

How do screw jacks enhance the performance of lifting and leveling applications?

Screw jacks are versatile mechanical devices that enhance the performance of lifting and leveling applications in several ways. Here are some ways in which screw jacks contribute to improved performance:

- Precise Positioning: Screw jacks offer precise positioning control, allowing for accurate adjustment of height or level. The threaded screw mechanism provides fine incremental movements, enabling operators to achieve the desired position with high precision. This level of control is crucial in applications where precise alignment, leveling, or height adjustment is required.

- Heavy Load Capacity: Screw jacks are capable of lifting and supporting heavy loads. They are designed to handle substantial weight and provide reliable load-bearing capabilities. The mechanical advantage of the screw thread allows for efficient transfer of force, enabling screw jacks to handle loads that would be impractical or challenging for other lifting mechanisms.

- Stability and Safety: Screw jacks offer stability and safety during lifting and leveling operations. The threaded screw mechanism ensures that the load remains secure and stable in the desired position, minimizing the risk of accidental movement or shifting. Screw jacks are designed with safety features such as locking mechanisms or braking systems to prevent unintended lowering or sudden movements, enhancing overall safety for both operators and the lifted load.

- Adjustability and Flexibility: Screw jacks provide adjustability and flexibility in lifting and leveling applications. They can be easily adjusted to accommodate different heights or levels, making them suitable for a wide range of applications. Screw jacks are available in various sizes, load capacities, and configurations, allowing for customization and adaptation to specific requirements.

- Reliability and Durability: Screw jacks are known for their reliability and durability. They are constructed with robust materials and designed to withstand heavy loads, frequent use, and harsh operating conditions. The screw thread mechanism is inherently resistant to wear and provides excellent load-holding capabilities, ensuring long-term performance and reliability.

- Manual or Motorized Operation: Screw jacks can be operated manually or with motorized systems, providing flexibility in choosing the appropriate mode of operation based on the specific application. Manual screw jacks are often used when precise control is required, while motorized screw jacks offer increased speed and automation for lifting or leveling larger or heavier loads.

By offering precise positioning, high load capacity, stability, adjustability, reliability, and flexibility in operation, screw jacks significantly enhance the performance of lifting and leveling applications. Their versatility and ability to handle heavy loads make them a preferred choice in various industries where controlled lifting, leveling, or positioning is essential.

Can screw jacks be customized for specific tasks like stage or platform adjustments?

Yes, screw jacks can be customized for specific tasks such as stage or platform adjustments. Customization allows screw jacks to meet the unique requirements of different applications, providing precise and reliable positioning and lifting solutions. Here’s how screw jacks can be customized for specific tasks: